Understanding 110mm Pipe Fittings

Definition and Overview – What are 110mm pipe fittings?

In the intricate dance of plumbing systems, 110mm pipe fittings emerge as the unsung heroes, seamlessly connecting sections of piping with precision and reliability. These fittings are specifically designed to accommodate 110mm pipes, which are a standard size in many South African drainage and water supply projects. Their robust construction ensures durability, even under the most demanding conditions, making them indispensable for both residential and commercial applications.

What sets 110mm pipe fittings apart is their versatility. They come in various shapes and configurations—elbows, junctions, couplers—that facilitate smooth transitions and efficient flow management. Whether you’re building a new drainage system or upgrading an existing one, understanding the definition and overview of these fittings illuminates their pivotal role in maintaining system integrity. Their clever design ensures they can withstand the rigours of daily use, providing peace of mind and long-lasting performance.

Common Materials Used – Types of materials (PVC, HDPE, metal, etc.)

Venturing into the world of 110mm pipe fittings reveals a fascinating array of materials, each chosen for its unique strengths and applications. In South Africa’s diverse plumbing landscape, these fittings must endure everything from scorching sun to underground dampness, demanding robust materials that stand the test of time. Among the most common are PVC, HDPE, and metal, each offering distinct advantages.

PVC 110mm pipe fittings are celebrated for their lightweight durability and resistance to corrosion, making them ideal for water supply and drainage systems. Their smooth interior surface minimizes flow resistance, ensuring efficient water movement. Meanwhile, high-density polyethylene (HDPE) fittings excel in flexibility and impact resistance, perfect for long-distance pipelines or areas prone to movement.

Metal, such as galvanized steel or brass, offers unparalleled strength and thermal stability—often chosen for industrial or high-pressure applications. Its resilience under extreme conditions makes it a staple in complex systems. To better understand, here’s a quick glance at common materials used in 110mm pipe fittings:

- PVC (Polyvinyl Chloride)

- HDPE (High-Density Polyethylene)

- Galvanized steel

- Brass

Each material lends a different character to the 110mm pipe fittings, transforming them from mere connectors into vital components of a reliable plumbing network. The choice of material often hinges on environmental factors, pressure requirements, and longevity expectations—elements that make every installation an adventure in engineering excellence.

Advantages of Using 110mm Pipe Fittings – Benefits in various applications

In the intricate dance of plumbing systems, 110mm pipe fittings emerge as the silent architects of reliability and efficiency. Their advantages extend beyond mere connectivity, embodying the resilience and adaptability required in South Africa’s dynamic environment. These fittings facilitate seamless water flow, reduce maintenance costs, and provide the flexibility needed for complex installations. Whether in urban plumbing or rural water management, the strength and versatility of 110mm pipe fittings make them indispensable.

Choosing the right fittings can transform a mundane network into a masterpiece of engineering finesse. Their capacity to withstand pressure, resist corrosion, and accommodate movement ensures longevity and peace of mind. Moreover, their compatibility with various materials broadens their application spectrum, making them suitable for everything from potable water transport to industrial effluent systems.

In many cases, the benefits of 110mm pipe fittings are most evident in demanding scenarios. For instance, impact-resistant HDPE fittings excel in areas prone to ground movement, while galvanized steel fittings offer unparalleled strength for high-pressure environments. The ability to adapt to diverse conditions is what truly elevates these fittings from functional components to vital elements of a resilient infrastructure.

Types of 110mm Pipe Fittings

Elbows and Bends – 90-degree and 45-degree elbows

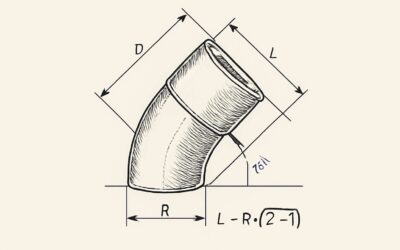

In the realm of 110mm pipe fittings, the elbows and bends are the silent architects of fluid flow, shaping the journey of water and waste with precision. Among these, 90-degree and 45-degree elbows stand out as the most versatile, each serving a distinct purpose in complex piping systems. A 90-degree elbow is the workhorse—redirecting flow sharply and efficiently, ideal for tight corners or space-constrained installations. Meanwhile, 45-degree elbows offer a gentler curve, reducing pressure loss and maintaining smoother flow, making them perfect for longer pipe runs.

Choosing the right type of 110mm pipe fittings hinges on understanding their applications and how they influence system performance. For instance, the use of 110mm pipe fittings with a 45-degree bend can significantly decrease turbulence, prolonging the lifespan of the piping network. Whether in drainage or irrigation systems, these fittings are vital to ensuring seamless operation, especially when navigating complex layouts. When selecting elbows and bends, consider the flow dynamics and installation constraints—sometimes, a subtle angle makes all the difference.

Reducers and Adapters – Steps and transition fittings

Within the labyrinthine corridors of piping systems, the transition points—where one diameter turns into another or where different materials unite—are the unsung heroes of fluid transport. 110mm pipe fittings, especially reducers and adapters, serve as the masterful artisans behind these seamless transitions. These fittings are crafted to bridge the gaps between various pipe sizes or materials, ensuring the flow remains unbroken and the pressure steady. Imagine a river meeting a tributary; the way the waters merge determines the harmony of the entire ecosystem. Similarly, these fittings facilitate smooth flow, reducing turbulence and wear over time.

For those seeking to expand or modify their piping networks, the selection of appropriate reducers and transition fittings is paramount. They are often categorized by their function:

- Reducing fittings – which diminish the pipe diameter gradually or abruptly, depending on the system needs.

- Adapters – which connect pipes made from different materials or sizes with precision.

Step-by-step, the process involves assessing flow requirements, compatibility with existing pipes, and installation constraints. When integrating 110mm pipe fittings with reducers or adapters, it’s vital to consider how these components influence pressure and flow velocity, especially in long, winding pipelines or in systems with high demand. Properly chosen transition fittings ensure that the journey of water or waste remains unobstructed, resilient, and efficient across South Africa’s diverse piping landscapes.

Tees and Crosses – Branching pipe configurations

Within the labyrinth of piping networks, the ability to branch seamlessly is paramount, and this is where 110mm pipe fittings such as tees and crosses reveal their true prowess. These fittings serve as the vital junctions—arterial crossroads—allowing fluid to diverge or converge with precision and minimal turbulence. A well-crafted tee or cross not only simplifies complex layouts but also ensures consistent flow dynamics, vital in the diverse South African landscape where water and waste systems must adapt to varying terrains and demands.

The versatility of 110mm pipe fittings shines brightest in their capacity to create intricate branching configurations. For instance, tees facilitate a three-way connection, enabling a lateral branch to feed off the main pipeline without disrupting the flow. Cross fittings, on the other hand, expand this capability to four-way intersections, turning a single pipeline into a dynamic grid. These components are indispensable in applications ranging from residential water supply to large-scale industrial drainage systems.

In practical terms, understanding the different types of 110mm pipe fittings helps in designing resilient and efficient networks. Consider the following:

- Standard branch tees for straightforward lateral connections

- Reducing tees to accommodate varying pipe diameters within the same network

- Cross fittings to establish multiple pathways, optimizing flow distribution

Each of these fittings embodies a meticulous balance between structural integrity and functional flexibility, making them essential for engineers and installers aiming for seamless pipeline integrations. Whether extending a drainage system or creating a complex water distribution grid, the strategic deployment of 110mm pipe fittings like tees and crosses ensures that the journey of fluid—be it water, sewage, or industrial effluent—remains uninterrupted, resilient, and primed for the challenges of South Africa’s diverse piping landscape.

Couplings and Connectors – Straight connectors and joining options

When it comes to the seamless union of pipes, the right couplings and connectors are the unsung heroes of any piping system. For those working with 110mm pipe fittings, the selection of straight connectors and joining options is crucial to ensuring durability and efficiency. These fittings serve as the vital links that maintain the integrity of water, sewage, or industrial flow across South Africa’s diverse terrains.

Among the most popular are straightforward straight connectors, designed to join two pipes of identical diameter with minimal fuss. Their simplicity belies their importance—they provide a secure, leak-proof connection that stands the test of time. For applications demanding more adaptability, there are transition fittings and adapters that facilitate changes in pipe size or material, ensuring your network remains resilient even when faced with complex specifications.

Consider the following essential types of 110mm pipe fittings for reliable connections:

- Standard straight connectors for uniform pipe joins

- Flexible couplings that accommodate slight misalignments or movement

- Transition adapters to bridge different pipe diameters or materials

Each of these components exemplifies functional elegance, crafted to uphold the structural integrity of your piping network. When deploying 110mm pipe fittings, selecting the right joining options ensures fluid journeys remain uninterrupted—be they water, sewage, or industrial effluent—regardless of South Africa’s demanding landscape.

Caps and Plugs – Sealing and terminating pipe runs

When it comes to sealing off or terminating a 110mm pipe run, the right caps and plugs are the unsung heroes of a leak-proof system. These fittings are essential for ensuring that no unwanted drips or dribbles spoil the flow—whether it’s water, sewage, or industrial effluent. Their purpose is simple: provide a secure, airtight, and watertight closure at the pipe’s end, giving your project a tidy finish and peace of mind.

110mm pipe fittings such as caps and plugs come in various materials, including durable PVC, robust HDPE, and corrosion-resistant metal, each suited to specific applications. For instance, PVC caps are ideal for clean water systems, while metal plugs might be the choice for industrial settings where strength and longevity are paramount. They are designed to withstand the demands of South Africa’s diverse terrain, from arid deserts to humid coastal regions.

Here’s a quick look at the typical types you’ll encounter:

- Standard pipe caps for easy termination

- Threaded plugs for secure sealing in threaded 110mm pipe fittings

- Flanged caps for larger, more complex setups requiring extra stability

Choosing the right 110mm pipe fittings for sealing and termination isn’t just about stopping leaks; it’s about safeguarding the integrity of your entire pipeline system. Properly fitted caps and plugs guarantee that your water or effluent journeys end on a high note—no surprises, just a neat, professional finish every time.

Applications of 110mm Pipe Fittings

Residential Plumbing – Drainage and waste systems

In the heart of every thriving home, especially in rural South Africa, reliable drainage and waste systems are the unsung heroes. 110mm pipe fittings play a crucial role in ensuring these systems operate smoothly, safeguarding the health and wellbeing of families. Their robust design makes them ideal for handling the demands of residential plumbing, where durability and ease of installation are paramount.

These fittings are particularly valued for their versatility in connecting various pipe sections. In many households, 110mm pipe fittings are used to create seamless drainage lines that carry waste away efficiently. They also facilitate the installation of complex piping networks, accommodating changes in direction with elbows and bends, or branching off with tees and crosses. This adaptability ensures that even the most intricate plumbing layouts can be achieved with confidence and minimal fuss.

For South African homes, where soil conditions and water flow requirements can vary widely, selecting the right 110mm pipe fittings is vital. They are often chosen for their resistance to corrosion and their ability to withstand the rigors of everyday use. Whether replacing old fittings or designing new drainage systems, these fittings offer peace of mind that your plumbing will stand the test of time, ensuring that rural households remain comfortable and connected to their communities.

Commercial and Industrial Uses – Sewage systems and irrigation

In the bustling world of commercial and industrial infrastructure, 110mm pipe fittings are the unsung heroes behind the scenes. These versatile components are essential for managing large-scale sewage systems, where reliable waste removal is non-negotiable. With their robust construction and ability to handle high flow volumes, 110mm pipe fittings ensure that effluent moves swiftly and efficiently, preventing costly blockages and environmental hazards.

Beyond sewage, these fittings are also pivotal in irrigation projects across South Africa’s agricultural heartlands. They facilitate the creation of expansive water distribution networks that keep crops thriving during dry spells. Whether used in the construction of complex piping layouts or simple branch-offs, 110mm pipe fittings provide the flexibility and strength needed for demanding applications.

In fact, their adaptability is further highlighted by their role in:

- Constructing durable stormwater drainage systems to prevent flooding

- Implementing large-scale irrigation channels for water conservation

- Connecting various pipe segments seamlessly in industrial setups

All of these applications underscore why 110mm pipe fittings are a staple in the toolkit of engineers and contractors across South Africa. Their resilience and ease of installation make them an indispensable part of modern infrastructure, ensuring communities remain connected, protected, and thriving under the toughest conditions.

Stormwater Management – Drainage solutions for heavy rainfall

In the unpredictable dance of nature’s fury, heavy rainfall tests the resilience of urban and rural landscapes alike. 110mm pipe fittings emerge as the silent guardians of stormwater management, their sturdy form harnessing the torrents that threaten to overwhelm. These fittings, with their robustness and precision, form critical links in drainage solutions designed to tame the tempest and safeguard communities from flooding.

Imagine a network of water channels, seamlessly interconnected by 110mm pipe fittings, channeling excess rainwater away from vulnerable areas. Their versatile design allows them to adapt to complex terrains and varying flow rates, ensuring that every drop finds its rightful course. Whether it’s constructing durable stormwater drainage systems or redirecting runoff in flood-prone zones, these fittings are the backbone of resilient infrastructure.

In regions prone to heavy downpours, the ability of 110mm pipe fittings to withstand extreme conditions becomes invaluable. They not only promote efficient water flow but also provide peace of mind—an unyielding shield against the chaos of nature’s fiercest moments. Their role is essential, transforming potential disasters into manageable flows and protecting both life and property with unwavering strength.

Electrical and HVAC Installations – Conduits and ventilation

In the intricate realm of electrical and HVAC installations, 110mm pipe fittings assume roles far beyond mere conduit connectors. These fittings serve as vital arteries, facilitating the seamless passage of electrical wiring and ventilation ducts through complex architectural frameworks. Their robust construction ensures stability and safety, crucial in environments where precision and durability are non-negotiable.

For HVAC systems, 110mm pipe fittings enable efficient ventilation by directing airflow through meticulously designed pathways. Their adaptability allows for intricate routing around obstacles, maintaining optimal air quality and system performance. In electrical applications, these fittings securely house conduits, safeguarding wiring from external elements and mechanical stress, thereby extending the lifespan of the installation.

Whether used in residential plumbing or industrial infrastructure, the versatility of 110mm pipe fittings shines through. Their capacity to accommodate various configurations—such as elbows, reducers, and tees—makes them indispensable in creating resilient, code-compliant systems. As the backbone of conduit and ventilation networks, these fittings exemplify reliability in the face of South Africa’s diverse climatic challenges.

Choosing the Right 110mm Pipe Fittings

Factors to Consider – Material, pressure rating, environment

When selecting 110mm pipe fittings, understanding the importance of material selection can’t be overstated. The durability, corrosion resistance, and compatibility with your project’s environment hinge on choosing the right material. For South African applications, PVC remains popular for its affordability and ease of installation, while HDPE offers exceptional flexibility and strength for underground or heavy-duty use. Metal fittings, such as galvanized steel, provide robustness in industrial settings but may require more maintenance.

Another critical factor is the pressure rating. Ensuring your 110mm pipe fittings can withstand the system’s operating pressure prevents costly failures down the line. Consider the environment—whether it’s exposed to extreme weather, chemical exposure, or heavy rainfall. For outdoor or stormwater management systems, fittings with high UV resistance and weatherproof properties are essential. Matching the right fitting to the specific application ensures longevity and optimal performance, making your investment truly worthwhile.

Compatibility and Standards – Industry standards and compatibility

When selecting 110mm pipe fittings, adherence to industry standards is paramount. These fittings must meet specific safety and quality benchmarks to ensure seamless compatibility across various systems. In South Africa, compliance with standards such as SABS (South African Bureau of Standards) guarantees that your 110mm pipe fittings are reliable and durable, whether for residential, commercial, or industrial applications.

Compatibility isn’t just about matching sizes; it involves understanding the standards governing pipe fittings. Using fittings that conform to recognized specifications minimizes the risk of leaks, pressure failures, or premature wear. It’s wise to verify that the fittings you choose are compatible with your pipes’ material and intended use. For example, PVC fittings should adhere to standards like SANS 1213, ensuring they fit perfectly and perform optimally in drainage or stormwater systems.

For added peace of mind, always check the manufacturer’s certification and confirm that the fittings are designed for the specific environment—be it underground, exposed outdoor conditions, or high-pressure systems. When these standards are met, your 110mm pipe fittings will not only fit perfectly but also offer peace of mind knowing they will stand the test of time.

Installation Tips and Best Practices

Preparation and Measurement – Accurate fitting measurements

In the realm of installing 110mm pipe fittings, precision is the key to unlocking a seamless flow of water or waste. Before diving into the assembly, it’s crucial to undertake meticulous preparation and measurement. An accurate measurement ensures that every 110mm pipe fitting aligns perfectly, preventing leaks and minimizing future disruptions. Remember, a slight miscalculation can cascade into costly repairs, so take your time and double-check each dimension.

When measuring for 110mm pipe fittings, use a reliable tape measure and confirm the diameter and length across different points. This diligence guarantees compatibility and optimal performance. To streamline the process, consider creating a simple checklist that includes verifying pipe diameter, assessing the environment, and selecting fitting types suitable for your project. In some cases, employing calibrated tools like pipe gauge or calipers can elevate your accuracy to the highest standard.

Installation tips also recommend dry-fitting components before final assembly. This step allows you to visualize the setup and make adjustments, avoiding unnecessary waste of materials. For complex configurations—such as branching or transitioning—careful preparation and measurement are vital for ensuring a secure and durable connection. When working with 110mm pipe fittings, precision isn’t just a step; it’s the foundation of a resilient piping system that stands the test of time.

Assembly and Connection – Proper installation techniques

In the intricate dance of installation, proper connection techniques for 110mm pipe fittings can spell the difference between a resilient system and a costly failure. Precision isn’t merely a virtue—it’s the backbone of enduring piping infrastructure, especially when working with larger diameters like 110mm pipe fittings. When assembling these components, meticulous attention to detail ensures seamless flow and minimizes the risk of leaks that could compromise entire systems.

One of the most critical steps is ensuring that all components are dry-fitted before final assembly. This allows for a visual inspection of the alignment and fit, making it easier to identify potential issues early. For more complex configurations, such as branching or transitioning, employing transition fittings and reducers with care ensures that the connection remains secure and leak-proof. Remember, a well-executed dry-fit acts as a rehearsal, enabling adjustments and saving time during the actual bonding process.

To enhance the integrity of your assembly, consider the following best practices:

- Clean all pipe ends thoroughly to remove debris and ensure a tight seal.

- Use appropriate sealing compounds or solvent welds compatible with your chosen material.

- Apply even pressure during connection to avoid deforming or damaging the fittings.

When joining 110mm pipe fittings, employing proper tools, such as pipe wrenches or coupling removers, can facilitate secure fittings without exerting undue stress. For added durability, some professionals advocate the use of clamps or mechanical fasteners, especially in high-pressure applications or harsh environments. These techniques not only secure the connection but also provide peace of mind, knowing that your system is built to stand the test of time.

Ultimately, the mastery of installation techniques for 110mm pipe fittings transforms a mere assembly into an art form—one that balances precision, durability, and efficiency. The subtle nuances of correct connection practices reveal themselves over time, as systems operate smoothly and maintenance needs diminish. In this realm, craftsmanship and methodical execution converge to create piping solutions that are as resilient as they are reliable.

Maintenance and Inspection – Ensuring longevity and leak prevention

Ensuring longevity and leak prevention in your piping system begins with diligent maintenance and inspection. With 110mm pipe fittings, the scale and complexity demand a meticulous approach to upkeep. Regular visual checks can reveal early signs of wear, corrosion, or misalignment, preventing costly repairs down the line. It’s essential to verify that all joints remain tight and free of debris, especially in high-pressure or industrial environments where the integrity of fittings is paramount.

Incorporating a routine maintenance schedule can significantly extend the lifespan of your piping infrastructure. For example, inspecting seals and connections periodically ensures they continue to perform optimally. When necessary, applying appropriate sealing compounds or replacing worn fittings can avoid leaks that compromise entire systems. Remember, a proactive approach to inspection transforms routine checks into a safeguard—preserving the seamless flow that 110mm pipe fittings are designed to facilitate.

For enhanced durability, consider using tools like pipe wrenches or mechanical fasteners during inspections. These not only help secure fittings but also prevent undue stress on joints. In high-pressure or demanding environments, employing clamps or additional connectors can provide peace of mind, reinforcing the system’s resilience. When combined with vigilant maintenance practices, these techniques create a robust and reliable piping network that stands the test of time.

Where to Buy 110mm Pipe Fittings

Local Suppliers – Hardware stores and plumbing centers

Finding reliable sources for 110mm pipe fittings in South Africa can transform a complicated plumbing project into a straightforward task. Local hardware stores and dedicated plumbing centers serve as treasure troves for these essential components, offering a range of options to suit any application. Whether you’re working on a residential drainage system or a large-scale industrial setup, having easy access to quality 110mm pipe fittings ensures your project stays on track.

Many hardware stores stock a comprehensive selection of 110mm pipe fittings, including elbows, connectors, and reducers. For more specialized needs, plumbing centers often provide expert advice and tailored solutions. Here are some popular places to explore:

- Major hardware chains with dedicated plumbing sections

- Specialist plumbing suppliers with extensive product ranges

- Local builders’ merchants that cater to both DIY enthusiasts and professionals

In South Africa, establishing a relationship with local suppliers not only guarantees prompt availability but also fosters trust in the quality of the fittings. This ensures that every junction, bend, or transition in your pipework performs flawlessly, keeping your project resilient for years to come.

Online Retailers – E-commerce options and considerations

When sourcing 110mm pipe fittings online, the options are as diverse as the projects they support. E-commerce platforms have revolutionized how professionals and DIY enthusiasts access these vital components, offering convenience without sacrificing quality. The key to a seamless transaction lies in selecting reputable retailers that prioritize authentic products and transparent pricing. From PVC to HDPE, many online retailers showcase a comprehensive range of 110mm pipe fittings suitable for every need.

Shopping online allows for comparison across brands and materials, often accompanied by detailed specifications and customer reviews that shed light on durability and performance. Many platforms also provide guidance on choosing the right fittings, ensuring your plumbing or drainage system remains resilient. When considering where to buy 110mm pipe fittings online, it’s wise to explore well-established suppliers known for their industry standards and reliable delivery services. This approach guarantees that each elbow, reducer, or connector arrives precisely when needed, keeping your project on schedule and up to standard.

- Verify the retailer’s reputation and customer feedback.

- Check for certifications and compliance with South African standards.

- Review shipping policies to ensure prompt and safe delivery.

Ultimately, purchasing 110mm pipe fittings online marries the convenience of modern commerce with the assurance of quality, making it an indispensable part of contemporary infrastructure development in South Africa. Whether for residential, commercial, or industrial use, these e-commerce avenues expand accessibility and streamline the procurement process, turning complex plumbing challenges into manageable endeavors.

OEM and Wholesale Suppliers – Bulk purchasing advantages

For those seeking a dependable source of 110mm pipe fittings in bulk, OEM and wholesale suppliers stand as the custodians of vast inventory and unparalleled purchasing advantages. These suppliers are the architects behind many large-scale infrastructure projects across South Africa, offering a strategic edge through cost-effective bulk purchasing. The ability to acquire large quantities of high-quality fittings not only streamlines project timelines but also fortifies budgets against fluctuating market prices.

Opting for wholesale suppliers often means gaining access to a diverse range of materials—PVC, HDPE, or even metal—each tailored to specific environmental and structural demands. These suppliers typically provide comprehensive certifications and compliance with South African standards, ensuring every 110mm pipe fitting meets rigorous industry benchmarks. Additionally, their streamlined logistics and reliable delivery services guarantee that your project remains on schedule, with fittings arriving precisely when needed.

When exploring where to purchase 110mm pipe fittings OEM or wholesale, consider establishing relationships with suppliers who offer the following benefits:

- Competitive pricing through bulk orders

- Access to a broad spectrum of materials and fittings types

- Consistent quality assurance and compliance with local standards

- Dedicated customer support and technical guidance

Engaging with these suppliers can transform complex plumbing and drainage challenges into seamless operations, turning a mundane procurement task into a strategic advantage. Whether you are managing residential developments or large industrial projects, sourcing 110mm pipe fittings from reputable OEM and wholesale suppliers ensures that every joint and connection upholds the integrity of your infrastructure—robust, reliable, and ready to withstand the test of time.

0 Comments