Overview of UPVC Pipe Fittings

Definition of UPVC Pipe Fittings

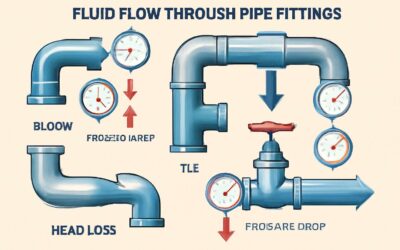

In the intricate dance of modern plumbing, UPVC pipe fittings emerge as silent maestros, orchestrating the seamless flow of life’s vital liquids. Their unassuming presence belies a resilient strength, forged from the very essence of UPVC—a material celebrated for its durability and resistance to corrosion. These fittings are the unsung heroes that bind, redirect, and sustain the arteries of infrastructure with an elegance that withstands the test of time and elements.

At their core, UPVC pipe fittings are specially designed connectors crafted from unplasticized polyvinyl chloride. They serve as the vital links in a complex network, enabling fluid transit with minimal fuss and maximum reliability. Their versatility is unmatched, making them indispensable in applications ranging from residential water supply systems to expansive industrial pipelines. Whether straight connectors, elbows, or tees, each piece complements the other in a symphony of engineered precision.

Here are some common types of pipe fittings upvc that often grace South African plumbing systems:

- Elbows for directional changes

- Tees for branching connections

- Couplings for joining pipes securely

- Reducers to adapt different diameters

Common Applications and Uses

In the shadowed corridors of South African infrastructure, UPVC pipe fittings carve silent pathways—channels of life flowing through the veins of cities and towns. Their applications stretch beyond mere plumbing, whispering secrets of resilience and adaptability. From the humble domestic water supply to sprawling industrial networks, these fittings are the unseen architects of modern civilization.

Particularly in environments where corrosion and wear threaten longevity, pipe fittings upvc stand as unwavering guardians. They are frequently employed in systems that demand both strength and flexibility, such as irrigation networks, drainage systems, and potable water pipelines. Their versatility ensures that whether you need to redirect flow or connect pipes of varying diameters, a fitting exists to meet the challenge.

- Residential plumbing systems rely on UPVC pipe fittings for their durability and ease of installation.

- Industrial setups use specialized fittings to withstand high pressure and corrosive elements.

- Municipal water management depends on these fittings for seamless, long-lasting connections.

In this intricate ballet of fluid dynamics, pipe fittings upvc are the silent choreographers—holding the flow steady, secure, and silent in their eternal dance beneath the surface. Their presence, often unnoticed, is vital to the lifeblood of every thriving South African city and beyond.

Advantages of UPVC Over Other Materials

In the realm of modern piping solutions, UPVC pipe fittings have emerged as the silent champions of durability and efficiency. Their resilience against the harsh South African climate and corrosive elements makes them an indispensable component in various infrastructure projects. These fittings are not only lightweight but also remarkably easy to install, reducing labor costs and project timelines—an enticing advantage for engineers and contractors alike.

What truly sets pipe fittings upvc apart from other materials is their exceptional resistance to chemical corrosion and UV degradation. Unlike metal counterparts prone to rust and wear, UPVC fittings maintain integrity over decades, ensuring long-term performance. This durability translates into fewer maintenance issues and a lower total cost of ownership, making them an economical choice for both municipal and residential applications.

Moreover, UPVC pipe fittings boast a versatility that is hard to match. They accommodate a variety of pipe sizes and configurations, providing flexibility in complex piping networks. Here’s a quick overview of their key benefits:

- Corrosion resistance that withstands aggressive environments

- Lightweight construction for easier handling and installation

- Cost-effectiveness over the lifespan of the system

- High chemical resistance suitable for diverse applications

In a landscape where reliability is paramount, pipe fittings upvc stand as a testament to engineering ingenuity—delivering peace of mind beneath the surface, quietly supporting the flow of life across South Africa’s vibrant cities and remote regions alike.

Types of UPVC Pipe Fittings

Elbows and Bivents

Elbows and bivents are essential components of pipe fittings UPVC systems. They allow for smooth directional changes and efficient flow management within plumbing networks. Elbows are typically used to bend pipes at specific angles, most commonly 45° or 90°, providing flexibility in tight spaces. Bivents, on the other hand, connect pipes at right angles with a T-shaped design, making them ideal for branch lines or junctions.

In South Africa, the demand for durable and corrosion-resistant pipe fittings UPVC is rising. These fittings are designed to withstand harsh environmental conditions and chemical exposure, making them perfect for both residential and industrial applications. When selecting elbows and bivents, consider the pipe diameter and angle to ensure a perfect fit and optimal flow.

- Ease of installation

- High chemical resistance

- Long-lasting performance

Couplings and Adapters

In the vast universe of pipe fittings UPVC, couplings and adapters serve as the enchanted bridges that seamlessly connect various segments of plumbing systems. These fittings are the unsung heroes, ensuring a secure, leak-proof junction that can withstand the relentless march of time and environmental challenges. Their versatility makes them indispensable in both residential and industrial settings across South Africa, where durability and chemical resistance are paramount.

Couplings are designed to join two pipes in a straight line, offering a simple yet vital solution for extending pipelines or repairing sections. Meanwhile, adapters provide the flexibility to transition between different pipe sizes or connection types, acting as the chameleons of the UPVC fittings world. For added convenience, many fittings feature ease of installation, allowing skilled technicians to swiftly craft a resilient network without fuss.

In an ever-changing landscape of piping needs, the diversity of pipe fittings UPVC ensures that every project, from intricate irrigation systems to major industrial pipelines, finds its perfect match. The fusion of strength, adaptability, and corrosion resistance makes these fittings the cornerstone of reliable, long-lasting plumbing infrastructure in South Africa’s demanding environments.

Tees and Cross Fittings

When it comes to expanding your plumbing universe, Tees and Cross fittings in the realm of pipe fittings UPVC are the true multitaskers. These fittings are not just connectors; they are the Swiss Army knives of piping, capable of splitting, merging, or rerouting flows with a mere twist of their design. In South Africa’s diverse environments, where water systems often face the harshest of conditions, these fittings stand tall—resistant to corrosion, chemical assault, and the relentless passage of time.

Tees are the quintessential three-way connectors, enabling a branch to sprout from the main pipeline. They are perfect for irrigation systems or complex drainage layouts, offering a seamless transition that keeps water flowing smoothly. Cross fittings, on the other hand, are the heavyweight champions, accommodating four connections and providing the backbone for more intricate piping networks. Their robust construction ensures durability in industrial applications and large-scale infrastructure projects.

For those who appreciate the finer details, consider this: the versatility of pipe fittings UPVC, especially Tees and Cross fittings, allows for a tailored approach to every project, whether it’s a modest residential install or an expansive industrial pipeline. The key is understanding how these fittings can morph your piping system into a resilient, leak-proof masterpiece—without breaking the bank or the pipe itself.

Caps and Unions

Caps and unions are essential components within the realm of pipe fittings UPVC, offering both protection and flexibility for your plumbing system. Caps are straightforward yet vital, sealing the ends of pipes to prevent leaks and contamination. They are particularly useful during system maintenance or when a future expansion is planned. Unions, on the other hand, provide a convenient way to connect and disconnect sections of UPVC piping without cutting or causing damage. This makes them indispensable in industrial setups or large installations where accessibility and ease of repair are priorities.

When selecting pipe fittings UPVC, it’s crucial to consider the specific application. For example, unions come in various designs—some with threaded connections, others with slip-fit options—each suited to different environments. Properly chosen caps and unions can enhance the durability and reliability of your piping network. In South Africa’s demanding conditions, where corrosion resistance and longevity are paramount, these fittings ensure your system remains leak-proof and resilient over time.

Reducers and Converters

In the world of plumbing, where precision marries resilience, the diversity of pipe fittings UPVC reveals its true artistry. Among these, reducers and converters stand as silent architects—bridging the gaps between varied pipe sizes or transforming connections with effortless grace. These fittings are the chameleons of the UPVC realm, adapting seamlessly to the complex demands of modern infrastructure.

Reducers, in particular, serve as the vital link, tapering the flow from a larger diameter to a smaller one, thus maintaining pressure and flow stability. Conversely, converters open a portal for compatibility—allowing UPVC pipes to connect with different materials or standards, ensuring a harmonious union in the piping symphony.

- Threaded reducers

- Slip-fit converters

—each type, a bespoke solution for specific environments, from industrial plants to residential systems.

In South Africa’s demanding climate, the choice of these pipe fittings UPVC becomes a testament to durability and foresight. They are not merely components—they are the unsung heroes that uphold the integrity of your plumbing network, whispering promises of leak-proof resilience and longevity through every twist and turn.

Specialized Fittings

When it comes to specialized pipe fittings UPVC, the options extend beyond basic connections. These fittings are crafted to address specific challenges in plumbing systems, especially in regions like South Africa where durability is paramount. Among these, socket weld fittings and flange adapters stand out as essential components for high-pressure applications. They provide secure, leak-proof joints that withstand harsh environmental conditions, ensuring long-term reliability.

In addition, the range of specialized fittings includes innovative solutions such as flexible couplings and compression fittings. These are particularly useful when dealing with uneven surfaces or when frequent maintenance is required. Their design allows for quick installation and easy disassembly, reducing downtime and labour costs.

Understanding the diversity of pipe fittings UPVC available helps professionals select the right components for each project. Whether it’s a complex industrial installation or a simple residential setup, these specialized fittings contribute significantly to the integrity and efficiency of the plumbing network. They are the quiet heroes in every pipeline, silently ensuring everything flows smoothly and securely.

Materials and Manufacturing Processes

Raw Materials Used in UPVC Fittings

Material integrity is the silent cornerstone of durable pipe fittings upvc. The raw materials used in manufacturing these fittings are primarily comprised of rigid polyvinyl chloride (PVC), which offers an impressive balance of strength, chemical resistance, and ease of installation. This synthetic polymer, when processed with precision, transforms into fittings that withstand the relentless pressures of South Africa’s diverse environments. The manufacturing process involves a careful blend of raw materials that are melted, extruded, and molded under controlled conditions to ensure uniformity and resilience.

These raw materials are selected not only for their mechanical properties but also for their environmental compatibility. Additives like stabilizers, lubricants, and impact modifiers are incorporated to enhance performance, especially in harsher climates. The result is a product that embodies both durability and adaptability. For pipe fittings upvc, quality control during manufacturing is paramount, as it guarantees that each piece maintains its integrity over time.

In essence, the raw materials and manufacturing processes serve as the unseen yet vital framework that elevates pipe fittings upvc from mere components to reliable solutions. Their meticulous design ensures longevity, making them an essential choice for plumbing and piping systems across South Africa’s demanding landscape.

Manufacturing Techniques

Manufacturing pipe fittings upvc is a meticulous craft driven by precision and innovation. The process begins with selecting high-quality raw materials—primarily rigid polyvinyl chloride (PVC)—which form the backbone of these durable fittings. Through advanced extrusion techniques, the raw material is heated, melted, and shaped into precise profiles, ensuring consistency across every piece produced. This method guarantees that each fitting can withstand South Africa’s diverse environmental pressures.

To further enhance performance, manufacturers incorporate specific additives during processing. These include stabilizers to prevent degradation, impact modifiers to improve toughness, and lubricants that aid in shaping the fittings smoothly. The manufacturing process often involves the following steps:

- Mixing raw materials with appropriate additives.

- Extrusion under controlled temperature and pressure.

- Cooling and molding into the final shape.

- Quality inspection to ensure resilience and uniformity.

By employing these advanced manufacturing techniques, producers create pipe fittings upvc that are not only robust but also environmentally compatible—adapting seamlessly to South Africa’s unique plumbing needs. It’s this combination of raw material integrity and refined production processes that makes pipe fittings upvc a trusted choice for countless applications.

Quality Standards and Certifications

Quality standards and certifications are critical aspects when selecting pipe fittings upvc, especially in South Africa’s demanding environments. Reputable manufacturers adhere to strict guidelines, ensuring that each fitting meets international and local quality benchmarks. These standards guarantee durability, chemical resistance, and long-term performance, making them suitable for various plumbing and industrial applications.

Manufacturers often pursue certifications such as ISO 9001, which attest to their commitment to consistent quality management. Such credentials assure clients that the pipe fittings upvc are produced under rigorous controls, minimizing defects and ensuring safety. Additionally, compliance with South African standards like SABS (South African Bureau of Standards) further validates the reliability of these fittings in local installations.

To maintain high standards, many producers implement thorough testing protocols, including pressure tests, impact resistance assessments, and UV stability evaluations. These quality checks ensure that every pipe fitting upvc can withstand environmental stresses and operational pressures. It’s this unwavering dedication to excellence that has positioned upvc fittings as a trusted choice across South Africa’s diverse plumbing landscape.

Key Features and Benefits

Corrosion Resistance

When it comes to pipe fittings upvc, one of the most compelling selling points is their impressive corrosion resistance. Unlike metal counterparts that rust at the first sign of moisture, UPVC fittings laugh in the face of water-induced decay. This durability is especially vital in South Africa’s diverse climate, where moisture and chemicals can turn a standard fitting into a soggy mess in no time. The inherent corrosion resistance of UPVC means fewer maintenance headaches, longer lifespan, and ultimately, a happier wallet.

Additionally, the non-reactive nature of UPVC makes it ideal for transporting a variety of fluids without compromising water quality or safety standards. This resilience ensures that pipe fittings upvc remain robust even after years of exposure to harsh environmental factors. For industrial, agricultural, or residential applications, this means peace of mind—no unexpected leaks or failures. The corrosion resistance factor isn’t just a bonus; it’s the backbone of reliable piping systems that stand the test of time.

- Extended service life with minimal upkeep

- Resistance to rust, chemical attack, and environmental wear

- Cost-effective solution with fewer replacements

So, if you’re looking for pipe fittings upvc that combine durability with ease of installation, their corrosion resistance features make them an obvious choice—saving you money and headaches in the long run!

Durability and Longevity

In the realm of piping solutions, few materials boast the resilience and longevity of pipe fittings upvc. Crafted from a resilient thermoplastic, these fittings stand as silent sentinels against the relentless march of time and environmental assault. Their durability is epitomized in their ability to withstand the onslaught of chemical attack, environmental wear, and physical stress, making them an indispensable component in South Africa’s diverse climates.

What truly sets pipe fittings upvc apart is their extended service life, often surpassing decades with minimal upkeep. Unlike metal alternatives prone to rust and corrosion, UPVC fittings maintain their integrity and performance over time. To illustrate, consider these core benefits:

- Resistance to rust, chemical attack, and environmental wear

- Ability to endure extreme temperature fluctuations common in South Africa

- Low maintenance requirements translating to cost savings

This combination of strength and resilience ensures that pipe fittings upvc remain unyielding in the face of harsh conditions, making them a cost-effective, long-term investment. In a world where reliability is paramount, these fittings weave a tale of endurance, safeguarding pipelines from failure and ensuring seamless fluid transport for years to come.

Ease of Installation

One of the standout qualities of pipe fittings upvc is their remarkable ease of installation, transforming what could be a labor-intensive task into a straightforward process. Thanks to their lightweight nature, even those with minimal technical experience can handle them confidently. This simplicity not only speeds up the installation process but also reduces labor costs—a win for project managers and contractors alike.

Another compelling advantage is the versatility of pipe fittings upvc, which are designed for seamless connection and compatibility across a wide range of pipeline configurations. Their smooth internal surface ensures minimal friction, making fluid flow more efficient and decreasing the chances of blockages or buildup over time. In fact, the design of upvc fittings allows for quick and secure assembly, often without the need for specialized tools.

- Corrosion-free connections, even in chemically aggressive environments

- Minimal preparation required before installation

- Compatibility with various pipe diameters and types

In South Africa’s fluctuating climate, these features prove invaluable, ensuring that pipe fittings upvc can be installed swiftly and reliably in diverse settings—from urban plumbing networks to rural irrigation systems. Their straightforward installation process paves the way for durable, long-lasting piping solutions that stand the test of time and environmental challenges.

Cost-Effectiveness

Cost-effectiveness is at the heart of the enduring appeal of pipe fittings UPVC. These fittings not only offer a wallet-friendly solution but also deliver exceptional performance, making them a preferred choice across South Africa’s diverse environments. Their affordability stems from streamlined manufacturing processes and the durability that minimizes the need for frequent replacements, ultimately reducing long-term expenses.

What truly sets pipe fittings UPVC apart is their ability to optimize fluid flow and withstand harsh conditions without the added cost of maintenance or corrosion protection. In many projects, their quick installation and reliable performance translate into significant savings—no need for specialized tools or extensive preparatory work. This efficiency accelerates project timelines and keeps budgets in check.

For those seeking a comprehensive overview, consider this:

- Durable, corrosion-free connections

- Minimal upkeep requirements

- Compatibility with various pipe diameters and types

These features coalesce into a cost-effective system that stands resilient, even in the face of South Africa’s fluctuating climate. Embracing pipe fittings UPVC means investing in a solution that marries affordability with unwavering reliability—a true triumph in pipeline technology!

Low Maintenance

In the shadowed corridors of pipeline technology, few materials evoke the eerie elegance of UPVC pipe fittings. Their key feature—low maintenance—serves as a silent guardian, warding off the relentless decay that plagues lesser materials. These fittings demand little more than an occasional inspection, a stark contrast to the relentless corrosion and frequent repairs that haunt metal alternatives.

What makes pipe fittings UPVC truly stand apart is their resilience against the corrosive elements that South Africa’s diverse climates conjure. No need for elaborate protective coatings or costly upkeep; their inherent properties shield against the relentless assault of moisture and chemicals. This steadfast durability ensures long-term performance, even in the harshest environments.

To grasp their true potential, consider this: UPVC fittings effortlessly adapt to various pipe diameters and types, forging seamless, corrosion-free connections that endure decades. Their ease of installation, combined with minimal upkeep, transforms complex projects into swift, cost-effective endeavors. In the end, pipe fittings UPVC are not just components—they are the silent sentinels of enduring pipeline integrity, whispering promises of reliability in a world of shifting elements.

Installation and Maintenance of UPVC Pipe Fittings

Installation Best Practices

In the realm of pipeline craftsmanship, the installation of UPVC pipe fittings stands as an art that demands precision and reverence. When venturing into the installation process, it’s crucial to adhere to best practices that ensure longevity and optimal performance. A meticulous approach not only preserves the integrity of the pipe fittings UPVC but also fortifies the entire system against unforeseen challenges.

One of the key elements is proper alignment. Ensuring that each fitting is correctly aligned minimizes stress and prevents leaks that could compromise the entire pipeline. Before joining, cleaning the ends of the UPVC pipe fittings thoroughly with a soft cloth removes debris and ensures a seamless connection. Applying a compatible primer followed by solvent cement creates a bond so strong that it becomes virtually inseparable—transforming the installation into a testament of engineering finesse.

For enhanced efficiency, it’s advisable to utilize a systematic approach. Consider the following:

- Measure carefully to avoid misfits and reduce waste.

- Ensure all fittings are compatible with the pipe diameter and pressure ratings.

- Allow sufficient curing time for solvent cement to set before pressurizing the system.

Routine maintenance of UPVC pipe fittings involves periodic inspections for signs of wear, such as minor cracks or discoloration. Addressing these issues early maintains the system’s integrity and prolongs its service life. Overall, mastering installation best practices for pipe fittings UPVC transforms a mundane task into a strategic act of craftsmanship that guarantees durability and efficiency in every pipeline journey.

Common Challenges and How to Avoid Them

Even the most meticulously planned pipeline can falter if common challenges in installation and maintenance are ignored. UPVC pipe fittings, celebrated for their corrosion resistance and longevity, still require a keen eye to avoid pitfalls that could compromise system integrity.

One frequent issue is improper alignment, which leads to leaks and increased stress on joints. Ensuring a precise fit isn’t just a good idea—it’s essential. Using the right tools and taking time to clean fittings thoroughly before joining can prevent misfits that cause headaches down the line.

Another challenge is premature degradation caused by exposure to harsh chemicals or UV radiation. Regular inspections can reveal early signs of wear, such as cracking or discoloration, allowing for swift intervention. Incorporating a routine maintenance schedule is vital for prolonging the lifespan of UPVC pipe fittings.

A simple, systematic approach can save a lot of trouble:

- Measure twice, cut once—accuracy is king.

- Verify compatibility with pipe diameter and pressure ratings.

- Allow solvent cement to fully cure before pressurizing the system.

By avoiding these common pitfalls, you can keep your UPVC pipe fittings functioning flawlessly, ensuring your pipeline remains leak-free and efficient for years to come.

Maintenance Tips for Longevity

In the realm of pipeline longevity, the secret lies in meticulous installation and vigilant maintenance of pipe fittings UPVC. These fittings, renowned for their resilience against corrosion and environmental assault, demand a delicate touch—an art of precision that transforms a simple connection into a lasting bond. Proper alignment is paramount; even a slight misfit can lead to leaks and undue stress on joints, undermining the entire system’s integrity.

To ensure enduring performance, regular inspections are essential. Look for early signs of wear such as discoloration or cracks, which may indicate exposure to harsh chemicals or UV radiation. Incorporating a systematic maintenance routine not only preserves the structural integrity of the UPVC pipe fittings but also extends their service life. Embrace a straightforward approach—measure twice, cut once, verify compatibility, and allow solvent cement to cure fully before pressurizing the system. This disciplined process safeguards your investment, ensuring your pipeline remains leak-free and functional for years to come.

Standards and Compliance

International and Local Standards

When it comes to pipe fittings upvc, adherence to international and local standards isn’t just a formality—it’s a safeguard for quality, safety, and durability. Regulatory frameworks like ISO and ASTM set rigorous benchmarks that manufacturers worldwide strive to meet, ensuring the fittings perform reliably across diverse conditions. In South Africa, local standards such as SABS (South African Bureau of Standards) further tailor these specifications to regional needs, particularly in water and waste management systems.

Compliance with these standards guarantees that pipe fittings upvc are manufactured with consistent quality, reducing risks of failure and environmental harm. The standards also facilitate seamless integration into existing infrastructure, making sure that fittings are compatible with other components and adhere to safety protocols. For professionals sourcing pipe fittings upvc, verifying certification isn’t just recommended; it’s essential for long-term operational integrity and regulatory approval.

Testing and Quality Assurance

In the realm of pipe fittings upvc, standards and compliance testing are the guardians of quality and safety. Manufacturers in South Africa and beyond undergo rigorous assessments to ensure their fittings meet strict international benchmarks like ISO and ASTM, along with regional standards such as SABS. These protocols aren’t just bureaucratic hurdles—they are essential barriers against subpar products that could compromise infrastructure integrity.

Quality assurance involves comprehensive testing processes that evaluate the fittings’ strength, chemical resistance, and long-term durability. This meticulous scrutiny guarantees that every pipe fitting upvc performs reliably under diverse conditions, from high-pressure water systems to corrosive waste channels. For professionals sourcing these fittings, verifying certification and adherence to standards isn’t optional—it’s a safeguard against failure and environmental damage.

Furthermore, compliance with these standards fosters seamless integration into existing piping networks. It ensures compatibility, safety, and peace of mind, especially in critical applications like municipal water supply and industrial waste management. When selecting pipe fittings upvc, always prioritize those with certified quality assurance, as this is the best way to secure long-lasting, effective infrastructure solutions.

Regulatory Guidelines

Standards and compliance regulatory guidelines are the silent guardians of integrity in the world of pipe fittings UPVC. These regulations don’t merely serve as bureaucratic checkpoints—they embody the moral obligation to safeguard infrastructure and communities. In South Africa, adherence to regional standards such as SABS ensures that pipe fittings UPVC meet rigorous safety and performance benchmarks, aligning with international protocols like ISO and ASTM. This confluence of standards creates a robust framework that elevates product reliability.

Ensuring compliance involves comprehensive assessments of pipe fittings UPVC to verify their strength, chemical resistance, and overall durability. Manufacturers must navigate a labyrinth of testing procedures, each designed to eliminate subpar components that threaten long-term performance. For professionals sourcing these fittings, verifying certification and adherence to such standards isn’t just a matter of due diligence—it’s a moral imperative. It guarantees that the infrastructure built with these fittings withstands the test of time and environmental challenges.

In this landscape, the importance of regulatory guidance cannot be overstated. They foster compatibility within existing piping systems, prevent failures, and uphold safety standards vital for municipal water supply and industrial waste management. When selecting pipe fittings UPVC, insistence on certified products rooted in strict compliance isn’t merely wise—it’s essential for enduring reliability and peace of mind.

Choosing the Right UPVC Pipe Fittings

Factors to Consider

Choosing the right pipe fittings UPVC requires a careful balance between functionality, durability, and compatibility with your specific application. In South Africa’s unique landscape, where water conservation and infrastructure resilience are paramount, selecting fittings that meet high standards is crucial. Factors such as pressure ratings, chemical resistance, and temperature tolerance influence the longevity and performance of your UPVC pipe fittings.

Beyond technical specifications, consider the installation environment—whether underground, above ground, or exposed to UV rays—and opt for fittings that are designed to withstand these conditions. The availability of fittings that adhere to reliable quality standards ensures peace of mind, especially in projects demanding long-term durability.

Most importantly, understanding the variety of pipe fittings UPVC offers can help you avoid costly mistakes. For example, choosing the right elbows, couplings, or reducers tailored to your system’s needs not only enhances efficiency but also minimizes potential issues down the line.

Compatibility with Pipeline Systems

Choosing compatible pipe fittings UPVC is essential to ensuring the integrity and longevity of your pipeline system. In South Africa’s demanding environment—where water conservation and infrastructure resilience are vital—fittings must seamlessly integrate with existing pipes and meet stringent standards. Proper compatibility minimizes the risk of leaks, pressure loss, and system failure.

When selecting pipe fittings UPVC, consider factors such as size, pressure ratings, and connection types. For example, using a fitting that matches your pipeline’s diameter ensures a secure, leak-free joint. Additionally, compatibility with your pipeline materials—whether PVC, UPVC, or other plastics—can significantly impact performance. In some cases, employing fittings with standardized threading or socket connections simplifies installation and enhances system robustness.

It’s also advisable to assess the environmental conditions your pipeline will face. Exposure to UV rays, underground placement, or high-temperature zones demands fittings designed for those specific challenges. By prioritizing compatibility and environmental resilience, you safeguard your investment and ensure your pipeline functions flawlessly over time.

Supplier and Vendor Tips

Securing the right UPVC pipe fittings supplier can make all the difference in ensuring a resilient and leak-free pipeline system. In South Africa’s diverse environment, choosing a vendor that prioritizes quality, compliance, and timely delivery is crucial. A reputable supplier offers not only certified pipe fittings upvc but also expert guidance tailored to your project’s unique demands.

When evaluating potential vendors, consider their adherence to international standards and the availability of technical support. Trusted suppliers often provide a comprehensive range of fittings, from elbows to reducers, that meet your specific size and pressure requirements. It’s wise to opt for vendors who source raw materials from reliable producers, guaranteeing durability and corrosion resistance in your fittings.

- Verify the supplier’s quality assurance processes

- Ensure they offer fittings compatible with your pipeline system

- Check for certifications that attest to the fittings’ resilience and safety

Partnering with a vendor that understands the environmental challenges faced in South Africa—like UV exposure or underground installation—helps you select pipe fittings upvc designed for longevity. This strategic choice safeguards your infrastructure investments, ensuring seamless, long-lasting performance over time!

Environmental Impact and Sustainability

Eco-Friendly Aspects of UPVC

In a world increasingly conscious of environmental preservation, the eco-friendly aspects of UPVC pipe fittings are gaining well-deserved recognition. Made from unplasticized polyvinyl chloride, UPVC pipe fittings are not only durable but also boast a significantly lower environmental footprint than traditional materials. Their long-lasting nature means fewer replacements and less waste, aligning perfectly with sustainable practices.

Moreover, UPVC pipe fittings contribute to resource conservation through energy-efficient manufacturing processes. These fittings are manufactured with minimal use of hazardous chemicals, reducing pollution during production. Their recyclability further underscores their eco-friendliness, allowing for reuse at the end of their long service life. Incorporating UPVC pipe fittings into pipeline systems is, therefore, a step toward a greener, more sustainable future—especially vital for communities and industries striving to reduce their ecological impact.

Recycling and Reuse

Environmental impact and sustainability are increasingly at the forefront of modern infrastructure decisions. UPVC pipe fittings are proving to be a responsible choice, thanks to their low ecological footprint. Their production process consumes less energy and involves fewer hazardous chemicals, making them a cleaner alternative to traditional materials. This means fewer pollutants are released into the environment during manufacturing, aligning with the global shift towards greener construction practices.

Recycling and reuse are fundamental elements of UPVC pipe fittings’ eco-friendliness. These fittings are designed to be highly recyclable, allowing them to be repurposed at the end of their long service life. This circular approach not only conserves resources but also reduces landfill waste. In fact, many suppliers now offer programs to take back used UPVC pipe fittings and recycle them into new products, reinforcing their contribution to sustainability.

To maximize their environmental benefits, industries and communities should consider integrating pipe fittings upvc into their pipeline systems. This choice supports a more sustainable future by minimizing waste, conserving resources, and lowering the overall carbon footprint of construction projects. Embracing UPVC fittings is a clear step forward in sustainable infrastructure development—one that balances performance with responsibility.

Future Trends in UPVC Fittings

As South Africa strides toward sustainable development, the environmental impact of construction materials becomes more than just a passing concern—it’s a moral imperative. UPVC pipe fittings are emerging as a shining example of eco-friendly innovation in pipeline systems. Their manufacturing process requires significantly less energy and involves fewer hazardous chemicals, making them a cleaner choice that aligns with the country’s growing commitment to greener infrastructure.

Looking ahead, the future of pipe fittings upvc is rooted in circular economy principles. Many suppliers now champion recycling programs, transforming used fittings into new, high-quality products. This approach not only conserves vital resources but also diminishes landfill waste, offering a tangible pathway toward sustainability. As industries and communities increasingly prioritize eco-conscious solutions, the adoption of UPVC fittings will likely become a standard in eco-friendly pipeline networks. Their durability combined with recyclability makes them an investment in both environmental health and the longevity of infrastructure projects.

0 Comments