Understanding Pipe Fittings and Their Angles

What are Pipe Fittings?

Understanding pipe fittings and their angles is crucial for anyone involved in plumbing or piping installation. Pipe fittings serve as the connectors that allow pipes to change direction, join different sizes, or adapt to various configurations. When it comes to precise angles, the pipe fitting 45 degree formula becomes an essential tool, especially in tight spaces where accuracy matters. This formula helps determine the correct cut or bend angle to ensure a seamless fit.

In practice, a 45-degree fitting creates an elegant transition between pipes, minimizing flow disruption. Knowing how to apply the pipe fitting 45 degree formula can save time and reduce errors on-site. Whether you’re installing new piping or repairing existing systems, understanding these angles helps maintain system integrity and flow efficiency. For more complex setups, a solid grasp of fitting angles ensures you avoid costly mistakes and achieve professional results every time.

Common Types of Pipe Fittings

In the intricate dance of plumbing, understanding pipe fittings and their angles is akin to mastering a language—each twist, turn, and bend must be precise. The pipe fitting 45 degree formula isn’t just a mathematical curiosity; it’s the silent hero behind seamless joints and elegant transitions. When space is tight and angles are critical, knowing how to apply this formula ensures your piping system remains both functional and aesthetically pleasing.

Among the common types of pipe fittings, the 45-degree elbow stands out for its versatility and subtlety. It gracefully redirects flow without causing turbulence or pressure drops. Whether working with cast iron or modern PVC, the application of the pipe fitting 45 degree formula simplifies the process, avoiding guesswork and costly rework. As a rule of thumb, this formula guides you in calculating the exact cut or bend needed, ensuring your piping conforms perfectly to the intended trajectory.

For those who prefer a quick reference, here’s a glance at typical fittings:

- Elbows (45° and 90°)

- Tees

- Couplings

- Reducers

In South Africa’s diverse plumbing landscape, where space constraints and varying materials challenge even seasoned professionals, the pipe fitting 45 degree formula emerges as an indispensable tool. It’s not just about fitting pipes; it’s about fitting the pieces of a puzzle with finesse and flair. After all, even the smallest angle can make a significant difference in the harmony of your piping system.

Importance of Accurate Angles in Pipe Fittings

In the complex realm of plumbing, precision is everything—especially when it comes to angles in pipe fittings. The significance of the pipe fitting 45 degree formula cannot be overstated; it’s the silent architect of seamless transitions and efficient flow. When space is limited or the system demands subtle bends, understanding how to accurately apply this formula ensures that every joint is both functional and visually pleasing.

Angles in pipe fittings are more than mere measurements—they are the blueprint for harmonious flow and structural integrity. A slight miscalculation can lead to turbulence, pressure drops, or leaks, undermining the entire system’s reliability. That’s why mastering the pipe fitting 45 degree formula offers a crucial advantage, enabling professionals to cut and bend pipes with confidence and precision, especially in South Africa’s diverse and often constrained plumbing environments.

Overview of 45 Degree Pipe Fittings

Understanding pipe fittings and their angles is essential for anyone involved in plumbing, especially when working within the tight constraints of South Africa’s diverse infrastructure. The 45 degree pipe fitting is more than just a bend; it’s a strategic element that influences flow dynamics and system reliability. When dealing with complex layouts, knowing how to accurately calculate or apply the pipe fitting 45 degree formula can mean the difference between a seamless system and one riddled with turbulence or leaks.

At its core, a 45 degree pipe fitting provides a gentle transition that reduces pressure loss and promotes smoother flow. This subtle angle is favored in scenarios where space is limited yet efficiency cannot be compromised. To achieve perfect bends, professionals often rely on the pipe fitting 45 degree formula, which guides precise measurements and cuts. Whether you’re fabricating custom bends or selecting pre-made fittings, mastering this formula is a game-changer in ensuring your installation’s integrity and longevity.

Mathematical Foundations of Pipe Fitting Angles

Basic Geometry of Pipe Bends

Mathematical foundations are the backbone of precise pipe fitting, especially when it comes to angles that make or break the flow—literally. When you’re navigating the world of pipe bends, understanding the basic geometry of pipe bends is essential. Imagine trying to fit a puzzle piece that’s slightly off—chaos ensues, and nobody wants a leaky puzzle! The pipe fitting 45 degree formula is rooted in simple trigonometry, where the key is to grasp how angles translate into lengths and curves. Essentially, it’s about translating a desired angle into an exact measurement that ensures seamless connections without guesswork.

In the realm of pipe fittings, every degree matters, but a 45-degree bend is particularly popular for its versatility. To calculate this angle accurately, one must understand the relationship between the hypotenuse, the adjacent, and the opposite sides—fundamental components of basic geometry. For instance, the length of the pipe segment can be derived from the formula involving sine and cosine functions, which are the heroes behind the pipe fitting 45 degree formula. Remember, a little math goes a long way in avoiding costly mistakes and ensuring the integrity of your piping system.

For those looking to master pipe bending, here is a quick rundown of the key steps:

- Determine the radius of the bend based on pipe diameter and application needs.

- Apply the sine or cosine of 45 degrees to find the appropriate length of pipe segments.

- Use these measurements to mark and cut accurately, ensuring a snug fit.

Understanding these geometric principles allows for precision and efficiency, making the pipe fitting 45 degree formula an invaluable tool for professionals across South Africa, where plumbing challenges demand both skill and mathematical finesse. After all, a well-calculated bend is a happy pipe—smooth, leak-free, and ready to do its job without fuss.

Trigonometric Concepts Involved

The mathematical backbone of precise pipe fitting isn’t just an academic exercise; it’s the secret weapon behind seamless plumbing systems. When working with pipe fitting 45 degree formula, understanding the underlying trigonometric concepts transforms guesswork into exactitude. The role of sine, cosine, and tangent functions becomes clear—they’re the compass guiding every measurement, ensuring each bend aligns perfectly with the intended angle.

At the heart of this calculation lies a simple yet powerful idea: translating angles into real-world measurements. For a 45-degree bend, the relationship between the hypotenuse and the sides of the triangle—dictated by these trigonometric functions—is crucial. The pipe fitting 45 degree formula leverages these relationships, enabling professionals to determine the precise length of pipe segments needed for a smooth, leak-proof connection. It’s this fusion of math and craftsmanship that elevates the art of pipe bending to an exact science.

- Determine the radius based on pipe diameter and application specifics.

- Apply sine or cosine of 45 degrees to find the necessary length of pipe segments.

- Mark and cut the pipe with precision, ensuring a perfect fit without guesswork.

By mastering these trigonometric concepts, South African plumbers and pipe fitters can confidently navigate complex bends, turning mathematical finesse into plumbing perfection. The pipe fitting 45 degree formula isn’t just a calculation; it’s the key to unlocking flawless pipe systems, where every curve tells a story of precision and expertise.

Angles in Pipe Fitting Design

In the intricate dance of pipe fitting design, understanding the mathematical foundations of angles is akin to mastering a silent symphony. Every bend and curve in a plumbing system is a whisper of geometry, a silent testament to precision and craftsmanship. The pipe fitting 45 degree formula is the key that unlocks this harmony, translating abstract angles into tangible measurements. It’s not merely about cutting pipes; it’s about sculpting a seamless flow—each curve an expression of meticulous calculation and artistry.

Angles in pipe fitting design serve as the silent architects of flow efficiency. When working with a 45-degree bend, grasping the interplay of sine, cosine, and tangent functions elevates the process from guesswork to an exact science. For instance, applying the cosine of 45 degrees helps determine the length of pipe needed for a perfect bend, ensuring every joint aligns flawlessly. These trigonometric relationships act as a compass for South African plumbers, guiding their hands through the labyrinth of measurements with unwavering confidence.

- Determine the radius based on pipe diameter and application specifics.

- Apply the pipe fitting 45 degree formula by using sine or cosine functions to calculate the necessary pipe segment length.

- Mark and cut with precision, transforming mathematical insight into practical perfection.

Through this elegant fusion of math and craftsmanship, each pipe bend becomes a story of exactitude—an ode to the mastery that transforms ordinary plumbing into an artful, leak-proof masterpiece. The pipe fitting 45 degree formula is not just a calculation; it’s the poetic heartbeat of flawless pipe systems, where every curve is a testament to precision and mastery.

The 45 Degree Pipe Fitting Formula Explained

Derivation of the Formula

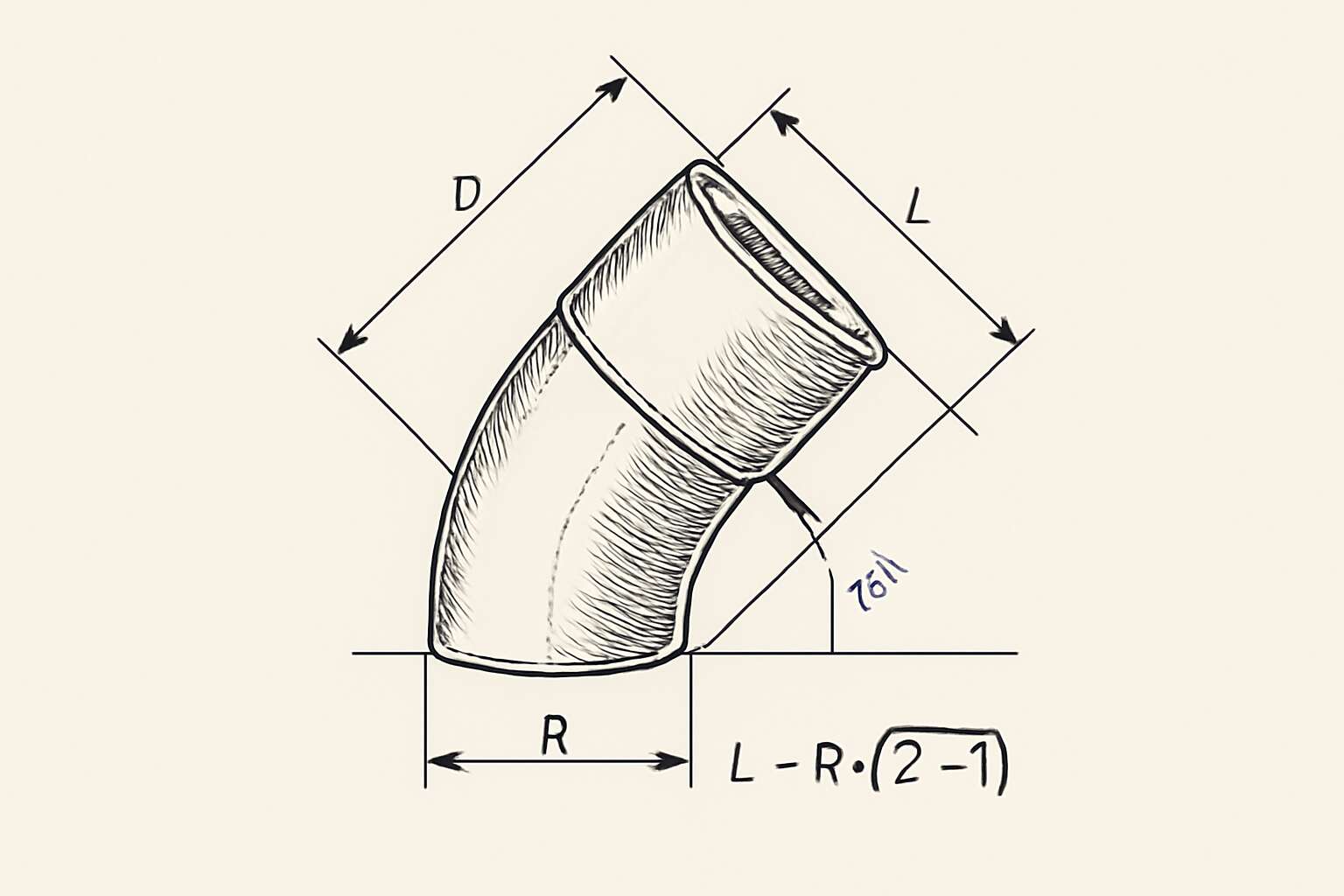

When plumbing dreams turn into nightmares, it’s often because someone underestimated the power of the pipe fitting 45 degree formula. This little piece of mathematical wizardry transforms a simple bend into a seamless, professional-looking pipeline—without requiring a degree in rocket science. The derivation of the formula is rooted in classic trigonometry, where the angles and lengths dance together in perfect harmony. Essentially, the formula helps determine the precise length of the pipe needed to make a 45-degree turn, ensuring optimal flow and minimal turbulence.

To make things crystal clear, the pipe fitting 45 degree formula is derived from the basic principles of right-angled triangles. By understanding the relationship between the hypotenuse, the adjacent, and the opposite sides, plumbers and engineers can accurately calculate the length of the pipe segment to achieve that ideal 45-degree bend. It’s a simple yet powerful tool that saves time, reduces waste, and guarantees a professional finish. Here’s a quick rundown of the core components involved:

- The length of the pipe from the bend’s start to the intersection point

- The angle of 45 degrees itself

- The trigonometric functions, primarily sine and cosine, that link angles to side lengths

Mastering the derivation of this formula is like unlocking the secret handshake of the piping world—once you get it, every bend feels like a walk in the park, or at least a well-calculated pipe layout. In South Africa, where plumbing standards are stringent and efficiency is king, knowing your pipe fitting 45 degree formula is not just clever; it’s essential for flawless installations.

Key Variables in the Formula

Understanding the key variables in the pipe fitting 45 degree formula is like unlocking a secret code that transforms ordinary pipe installation into a masterpiece of precision. At the heart of this mathematical symphony are the basic principles of right-angled triangles, where the relationship between the hypotenuse, the adjacent side, and the opposite side reveals the exact length of pipe needed for a perfect 45-degree bend.

Think of the variables involved: the length of the pipe from the start of the bend to the intersection point, the 45-degree angle itself, and the trigonometric functions—primarily sine and cosine—that connect these elements seamlessly. These functions serve as the bridge, translating the angle into tangible measurements that ensure smooth flow and minimal turbulence within the pipeline.

- The hypotenuse, which is the actual length of the pipe segment required for the bend.

- The adjacent side, representing the straight run of pipe before or after the bend.

- The angle of 45 degrees, dictating the precise orientation of the bend.

Mastering these variables means every pipe fitting 45 degree formula becomes a tool of mastery, enabling plumbers to craft piping systems with an almost artistic finesse. It’s a dance of numbers that guarantees efficiency, reduces waste, and elevates the quality of installation—especially crucial in South Africa’s demanding plumbing standards. When variables align perfectly, the result is a pipeline that flows like poetry in motion—fluid, efficient, and impeccably executed.

Step-by-Step Calculation Process

Calculating the perfect 45-degree bend in piping isn’t merely a matter of guesswork; it’s an elegant dance of geometry and precision. The pipe fitting 45 degree formula transforms complex angles into straightforward measurements, ensuring every installation is both functional and aesthetically pleasing. The process begins with identifying the key variables—most notably, the hypotenuse, the adjacent side, and the angle itself—and then applying basic trigonometric functions to find the exact length of pipe needed.

Here’s how it unfolds: first, measure the straight run of pipe before the bend. Next, utilize the sine or cosine functions to relate this measurement to the hypotenuse—the actual pipe segment required for the bend. An easy way to visualize this is through the use of the following

- trigonometric equations,

- which convert the 45-degree angle into tangible pipe lengths.

This method ensures minimal waste and a seamless fit, especially vital within South Africa’s demanding plumbing standards.

Mastering the pipe fitting 45 degree formula is akin to acquiring a secret language, one that guarantees the creation of pipelines flowing with the grace of a well-rehearsed ballet. Precision in these calculations not only elevates the artistry of plumbing but also translates into efficiency and durability—qualities every plumber aspires to uphold.

Practical Examples and Calculations

In the realm of precision pipe fitting, the 45 degree angle is more than a mere geometric construct; it is a symphony of mathematical finesse and practical application. The pipe fitting 45 degree formula unlocks the secret to crafting bends that marry form with function, minimizing waste while maximizing flow efficiency. This elegant equation transforms complex spatial relationships into tangible measurements, ensuring every pipe installation adheres to both engineering standards and aesthetic harmony.

Practical examples of the pipe fitting 45 degree formula reveal its profound utility. For instance, when designing a pipeline that must navigate around structural obstructions, applying trigonometric principles allows for exact calculations of pipe lengths required for seamless bends. This is where the formula’s true power shines—converting the hypotenuse, adjacent, and opposite sides into precise measurements that align with the angle of 45 degrees. Such calculations are indispensable within South Africa’s demanding plumbing standards, where accuracy directly influences durability and safety.

Consider an installation scenario: measuring a straight run of 1 meter before the bend, then employing the pipe fitting 45 degree formula, which involves calculating the hypotenuse using cosine functions. The resulting measurement ensures the bend fits perfectly, with minimal waste and optimal flow. This process exemplifies how the pipe fitting 45 degree formula is not merely theoretical but a practical tool—one that guides plumbers through complex geometries with confidence and clarity.

Application of 45 Degree Formula in Pipe Installation

Designing Pipe Layouts

In the intricate realm of pipe installation, precision is paramount—especially when designing pipe layouts that demand seamless transitions and optimal flow. The application of the pipe fitting 45 degree formula becomes instrumental in achieving these objectives, transforming abstract angles into tangible, functional components of a piping system. When architects and engineers in South Africa approach complex piping networks, this formula offers a reliable mathematical foundation to determine bend lengths and angles with unwavering accuracy.

By leveraging the pipe fitting 45 degree formula, professionals can craft layouts that minimize turbulence, reduce pressure loss, and enhance overall efficiency. Whether navigating tight spaces or ensuring smooth directional changes, this formula aids in calculating the exact bend radius and length, facilitating a harmonious flow of liquids or gases. Integrating this mathematical principle into pipe installation design not only streamlines the construction process but also ensures adherence to safety standards and operational excellence.

Selecting the Right Fitting

In the intricate art of pipe installation, selecting the correct fitting is as vital as the precise calculation behind it. The application of the pipe fitting 45 degree formula simplifies this process, providing a dependable method for determining the optimal bend length and angle. When navigating complex piping networks across South Africa, professionals rely on this mathematical foundation to ensure seamless transitions and efficient flow. Properly applied, the pipe fitting 45 degree formula helps in achieving smoother directional changes, minimizing turbulence, and reducing pressure loss—crucial factors in maintaining operational excellence.

By understanding the core variables involved in the pipe fitting 45 degree formula, engineers and installers can make informed decisions. This knowledge is especially valuable when working in tight spaces or on systems that demand high precision. Whether designing new layouts or troubleshooting existing piping, the formula guides the selection of fittings that perfectly match the system’s flow requirements, thereby enhancing safety and performance.

Using the Formula in CAD Software

In modern pipe installation, especially within complex networks across South Africa, the application of the pipe fitting 45 degree formula in CAD software has become indispensable. This mathematical tool allows engineers and installers to accurately model bends and directional changes, ensuring optimal flow and minimal turbulence. Using CAD, professionals can input core variables from the pipe fitting 45 degree formula to generate precise bend lengths and angles, streamlining the planning process.

Integrating the pipe fitting 45 degree formula into digital design offers several advantages. It reduces the risk of errors and ensures that fittings are perfectly tailored to the specific requirements of the system. When working in tighter spaces or on high-pressure systems, this accuracy becomes even more critical. By leveraging CAD tools alongside the pipe fitting 45 degree formula, designers can visualize the entire piping layout, making adjustments before physical installation begins—saving both time and resources.

Common Mistakes to Avoid

In the intricate dance of pipe installation, a misstep can ripple through a system like a discordant note in a symphony. The application of the pipe fitting 45 degree formula, when wielded with precision, transforms this choreography into a harmonious flow. Yet, even seasoned engineers in South Africa’s bustling infrastructure projects occasionally stumble into common mistakes that threaten to distort this melody.

One frequent pitfall is neglecting to double-check the key variables before calculating bend lengths. Overestimating or underestimating these values can result in fittings that are either too tight or too loose, compromising both safety and efficiency. Additionally, rushing through the process without verifying angles can lead to misaligned pipes, causing turbulence and increasing pressure drops. Remember, the beauty of the pipe fitting 45 degree formula lies in its accuracy—disregarding its nuances can turn a simple bend into a problematic kink in the system.

To avoid these pitfalls, professionals should always cross-reference their calculations with real-world measurements and leverage CAD software for validation. Furthermore, maintaining a meticulous step-by-step approach ensures that each angle and length aligns perfectly with the intended design. In the world of pipe fitting, precision isn’t just ideal—it’s imperative, especially when working within the tight confines of South African infrastructure networks. Embracing these best practices guarantees that every bend is a testament to engineering excellence, not a flaw waiting to surface.

Tools and Resources for Accurate Pipe Fitting

Measurement Instruments

Mastering the art of accurate pipe fitting measurement is akin to wielding a magic wand—except instead of spells, you rely on precise tools. When dealing with intricate 45 degree pipe fittings, having the right instrument can make the difference between a perfect fit and a leaky catastrophe. A reliable digital angle finder or a high-quality protractor is essential for ensuring your pipe fitting 45 degree formula is applied flawlessly. These tools not only save time but also elevate your craftsmanship beyond amateur hour.

To further refine your measurements, consider investing in calibration accessories or digital measurement devices that integrate seamlessly with CAD software. Such resources streamline complex calculations, especially when working on elaborate pipe layouts. For those who prefer traditional methods, a sturdy combination square can still do wonders, provided it’s well-calibrated. Remember, in the realm of pipe fitting, precision is king—so don’t skimp on tools that guarantee accuracy.

- Digital angle finders for quick, precise measurements

- High-quality protractors for manual accuracy

- Calibration tools to keep your instruments in check

- CAD software with built-in measurement tools for complex calculations

Equipping yourself with these cutting-edge measurement instruments ensures your pipe fitting 45 degree formula is never compromised, paving the way for flawless pipe installations across South Africa’s diverse industrial landscape. Because when it comes to pipework, a little precision goes a long way—and saves everyone from future headaches.

Calculation Tools and Apps

In the intricate dance of pipe fitting, having the right tools and resources at your disposal can spell the difference between a seamless installation and a costly mess. When dealing with the pipe fitting 45 degree formula, precision becomes paramount—no room for guesswork in the world of industrial craftsmanship. Fortunately, today’s technological landscape offers an array of measurement tools and applications designed to streamline this process, ensuring every angle is spot-on.

For those who prefer the tactile satisfaction of manual measurement, high-quality protractors and calibrated combination squares remain stalwart allies. Yet, modern digital angle finders are revolutionizing the game, delivering quick and highly accurate readings that can be relied upon even in tight or awkward spaces. Additionally, digital measurement devices that seamlessly integrate with CAD software have made complex pipe layout calculations not only more manageable but also far more reliable.

To enhance your toolkit further, consider exploring specialized apps tailored for pipe fitting calculations. These applications often feature built-in functions for the pipe fitting 45 degree formula, simplifying the process—especially when working under tight deadlines or on elaborate piping systems. An ordered list of some invaluable resources includes:

- Digital angle finders for swift, precise measurements

- High-quality protractors for manual accuracy

- Calibration accessories to maintain instrument integrity

- CAD software with dedicated measurement tools for complex pipe layouts

- Mobile apps designed explicitly for pipe fitting calculations

By investing in these tools and resources, South African engineers and technicians can confidently execute projects with an unwavering commitment to precision. The mastery of the pipe fitting 45 degree formula hinges on the quality of measurement—there’s little room for compromise when every degree counts in the grand tapestry of industrial pipework.

Technical Manuals and Standards

In the realm of precision engineering, where every degree determines the flow of progress, the importance of adhering to established standards cannot be overstated. For South African engineers and technicians, consulting comprehensive technical manuals and standards is essential when applying the pipe fitting 45 degree formula. These authoritative resources serve as the silent guardians of accuracy, ensuring that each bend and angle aligns perfectly with industry specifications. They provide a detailed blueprint, safeguarding against costly errors and enhancing the integrity of every piping system.

Within these manuals, you’ll discover meticulously documented measurement protocols, calibration procedures, and safety guidelines that elevate the craft of pipe fitting. Moreover, national and international standards often include reference tables and calculation sheets tailored specifically for pipe fitting angles, including those critical 45-degree bends. Embracing these standards transforms the complex geometry of pipe fitting into a harmonious dance of precision and reliability.

- Consult official technical manuals from recognized South African standards bodies.

- Adopt measurement instruments that comply with international calibration norms.

- Utilize industry-specific standards to verify the accuracy of your calculations.

By immersing oneself in these authoritative resources, professionals harness the full potential of the pipe fitting 45 degree formula, turning theoretical knowledge into a tangible craft of mastery. It’s a symphony of standards and skills that ensures every project flows seamlessly from blueprint to reality—where precision is not just desired but demanded.

Professional Tips for Precision

Precision in pipe fitting is not just a skill—it’s an art form that demands the right tools and resources. When working with the pipe fitting 45 degree formula, every fraction of a degree can impact the integrity of the entire system. Authentic measurement instruments, such as calibrated protractors and digital angle finders, become the silent allies in this pursuit of perfection. These tools, endorsed by international calibration standards, ensure every bend aligns flawlessly with industry specifications.

To elevate your craftsmanship, consider leveraging advanced calculation tools and apps tailored specifically for pipe fitting calculations. These resources accelerate the process and reduce human error, safeguarding the accuracy of your 45-degree bends. For professionals in South Africa, accessing reputable technical manuals and standards from recognized bodies guarantees that your measurements remain consistent, reliable, and compliant with national norms.

In the end, combining high-quality tools with authoritative resources transforms the complex geometry of pipe fitting into an exact science—where precision is not merely a goal, but an unwavering standard. Every project becomes a symphony of accuracy, ensuring seamless flow and durability in every piping system crafted.

Maintenance and Troubleshooting of 45 Degree Pipe Fittings

Signs of Fitting Misalignment

In the intricate world of pipe fitting 45 degree formula, undetected misalignments can lead to costly failures. Proper maintenance ensures that every bend maintains its precise angle, safeguarding the integrity of the entire piping system. When signs of fitting misalignment appear, it’s a signal that meticulous troubleshooting is required. Often, these signs manifest as uneven flow, unusual vibrations, or visible stress on the joints—clues that the angle has deviated from its intended design.

Addressing these issues begins with a careful inspection, utilizing measurement instruments like laser levels or digital angle finders to verify the accuracy of the pipe bend. If discrepancies are found, realignment or replacement of the fitting becomes necessary. Remember, the pipe fitting 45 degree formula is instrumental in predicting the precise angles, but real-world conditions can sometimes challenge these calculations. Regular checks and prompt correction of misalignments are essential to prevent long-term damage and ensure seamless operation of the piping network.

Corrective Procedures

In the shadowed realm of pipe fitting 45 degree formula, precision is the only sanctuary against chaos. When misalignments creep into the system, they often whisper their presence through uneven flow or subtle vibrations—eerily reminiscent of a ghostly disturbance in a silent corridor. The delicate art of troubleshooting demands a keen eye and the right tools, such as laser levels or digital angle finders, which serve as the lanterns illuminating the unseen cracks in the system.

Addressing misalignment involves an intricate dance of inspection and correction. Sometimes, the remedy is as simple as reorienting the fitting; other times, it requires complete replacement. Remember, the pipe fitting 45 degree formula is a guiding star in this process, enabling accurate predictions of angles. Yet, real-world conditions may challenge these calculations—making regular checks essential. In this dark universe of piping, vigilance and swift intervention are the only shields against long-term damage, ensuring the system’s silent, unwavering pulse.

Preventive Measures

In the meticulous realm of pipe fitting 45 degree formula, maintenance and troubleshooting transcend mere routine—they become a ritual of precision that safeguards the integrity of complex piping systems. An unnoticed misalignment, subtle yet insidious, can ripple through the network, causing uneven flow or unwelcome vibrations that challenge even seasoned technicians. Vigilance, therefore, is the cornerstone of effective pipe fitting management in South Africa’s diverse industrial landscape.

Preventive measures are vital in maintaining the seamless operation of 45-degree pipe fittings. Regular inspection using advanced measurement instruments—such as laser levels and digital angle finders—can preempt deviations before they escalate. It’s crucial to adhere to established standards, ensuring each fitting conforms to the predetermined angles derived from the pipe fitting 45 degree formula. This proactive approach reduces downtime and mitigates costly repairs, fostering system longevity and operational reliability.

Addressing misalignments often requires a nuanced approach. Sometimes, a simple reorientation of the fitting suffices; other scenarios demand a comprehensive replacement. To streamline troubleshooting, consider employing a structured approach:

- Identify the source of misalignment through precise measurement tools.

- Compare actual angles against calculations from the pipe fitting 45 degree formula.

- Execute corrective adjustments—repositioning or replacing fittings as needed—while maintaining adherence to the formula’s predictions.

Throughout this process, maintaining a vigilant eye and employing the right tools ensures the system’s silent, unwavering pulse endures. In this shadowy universe of piping, such diligence becomes a shield against chaos, transforming what might seem a delicate art into a fortress of reliability and precision.

When to Consult Professionals

In the shadowy corridors of industrial piping, even the faintest misalignment can unleash chaos—vibrations, leaks, or system failure lurking just beyond the horizon. When maintaining pipe fitting 45 degree fittings, vigilance is paramount. An unnoticed deviation from the precise angle can ripple through the network, threatening the harmony of the entire system. Troubleshooting, therefore, demands both patience and an intuitive grasp of the pipe fitting 45 degree formula, which acts as the map through this labyrinth of complexity.

While minor adjustments—such as reorienting a fitting—may seem straightforward, persistent misalignments often whisper a darker truth: the need for professional intervention. When signs of misfit become apparent, it’s crucial to consult seasoned technicians who can employ advanced measurement instruments—laser levels or digital angle finders—to uncover the root cause. In some cases, a comprehensive replacement of the fitting may be the only recourse to restore order.

- Begin by precisely measuring the angle using a digital angle finder, comparing it against the predictions of the pipe fitting 45 degree formula.

- Identify any deviation, no matter how subtle, then decide whether a simple repositioning or a full replacement is warranted.

- If needed, escalate the issue to professionals who possess the specialized tools and expertise to execute flawless realignments.

In this realm of shadows and steel, the mastery of troubleshooting—guided by the pipe fitting 45 degree formula—becomes a safeguard against chaos. When doubts linger or the system’s integrity is compromised, calling in the experts is not just prudent; it’s essential to preserve the silent, unwavering pulse of your piping network.

0 Comments