Understanding Orthographic Pipe Fitting Symbols

Definition of Orthographic Drawing in Piping Systems

In the intricate dance of piping design, understanding orthographic pipe fitting symbols can be drawn as is akin to deciphering a secret language—crucial for clarity and precision. Orthographic drawing, often dismissed as mere technical jargon, actually serves as the blueprint of the piping universe. It provides a two-dimensional representation where each symbol tells a story of how different pipe components connect, bend, and branch out. These symbols are not just random doodles; they are standardised visual codes that ensure everyone from engineers to fabricators speaks the same language.

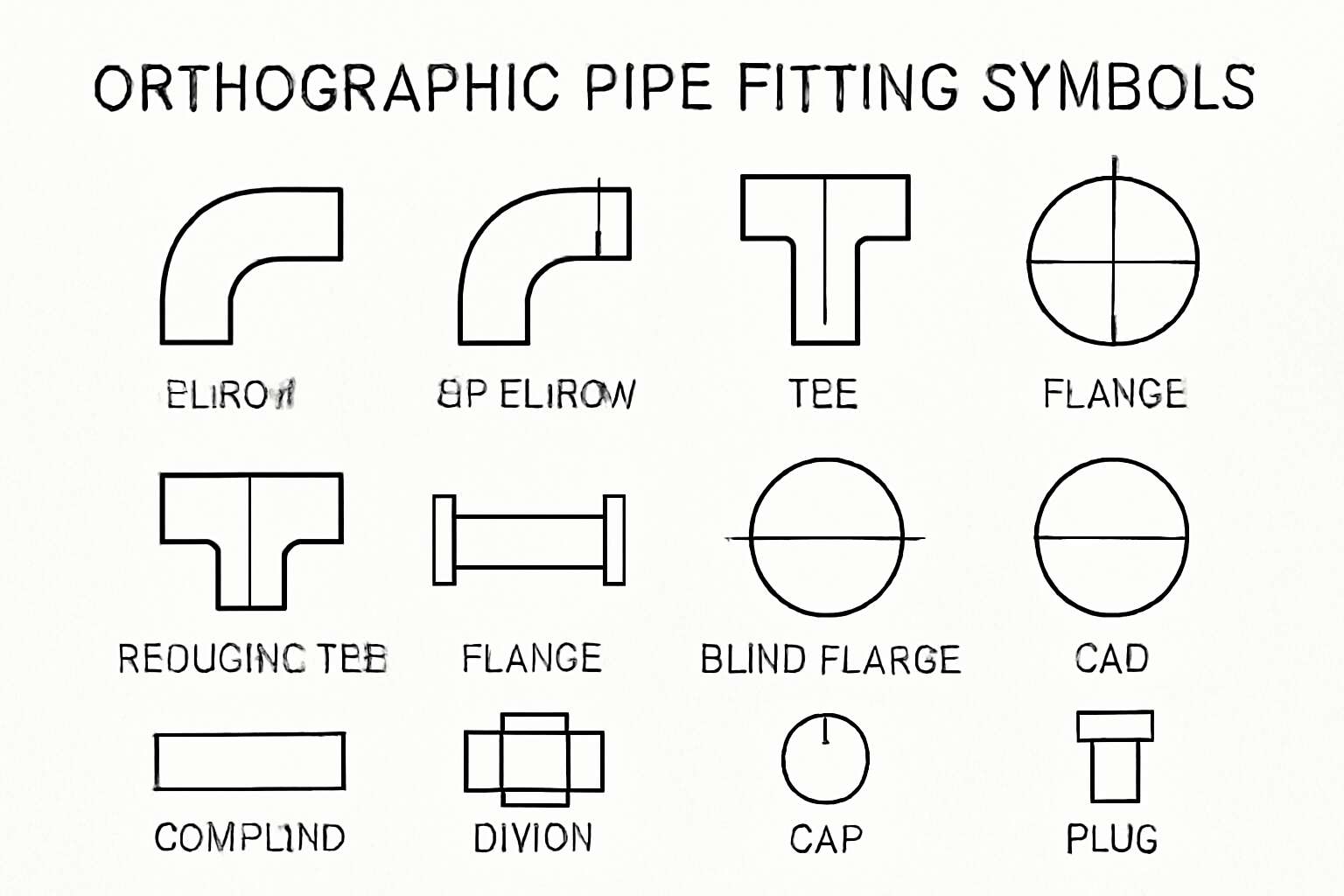

So, how exactly can orthographic pipe fitting symbols be drawn as? They typically include standardised shapes and annotations that denote fittings like elbows, tees, reducers, and flanges. Mastering this visual shorthand can significantly streamline communication across project teams. To make it easier, here’s a quick rundown:

- Identify the type of pipe fitting required.

- Use standard symbols to denote each fitting—such as a 45-degree elbow or a T-junction.

- Apply consistent line styles and annotations to specify size, material, and orientation.

In essence, understanding how orthographic pipe fitting symbols can be drawn as transforms complex piping layouts into clear, universally understandable diagrams—saving time, avoiding errors, and keeping projects ticking smoothly along.

Importance of Symbols in Pipe Fitting Diagrams

In the intricate realm of piping design, symbols are the silent language that transforms complex layouts into universally understood blueprints. The importance of orthographic pipe fitting symbols cannot be overstated—they are the key to ensuring seamless communication between engineers, fabricators, and project managers. When these symbols are correctly applied, they serve as visual shorthand, capturing the essence of each fitting with precision and clarity. This clarity not only accelerates project timelines but also minimises costly errors that can arise from misinterpretation.

Understanding how orthographic pipe fitting symbols can be drawn as is essential for creating accurate diagrams. These symbols beautifully blend standardised shapes with annotations that specify the type of fitting—be it a gentle bend or a branching tee. Incorporating these visual cues into your drawings ensures that everyone involved can interpret the design effortlessly. Whether depicting a 45-degree elbow or a flange connection, these symbols make the blueprint come alive, turning a jumble of lines into a coherent narrative of the piping system.

Standards and Conventions for Pipe Fitting Symbols

Consistency in drawing orthographic pipe fitting symbols is vital for clear communication across projects. Standards and conventions govern how these symbols can be drawn as, ensuring uniformity and reducing misunderstandings. Adhering to recognised guidelines, such as those set by industry organisations, guarantees that every symbol accurately represents its real-world counterpart. This standardisation simplifies collaboration between engineers, fabricators, and inspectors alike.

To maintain clarity, many professionals follow established conventions when illustrating pipe fittings. For instance, a 45-degree elbow is consistently drawn with a specific angled symbol, while a T-junction uses a distinct shape to denote branching. Recognising these standards allows for quick interpretation and seamless integration into detailed piping diagrams. Remember, these conventions are not arbitrary—they are the backbone of precise, professional pipe fitting drawings.

Understanding how orthographic pipe fitting symbols can be drawn as is crucial. It helps prevent costly errors, accelerates project timelines, and improves overall communication. By following standardised practices, you ensure that each symbol conveys the correct information, whether depicting a flange connection or a bend. This adherence to standards keeps your piping diagrams accurate, consistent, and easily understood by everyone involved.

Common Types of Pipe Fitting Symbols and Their Drawings

Elbow Symbols and Their Orthographic Representation

In the shadowed corridors of engineering, where precision is cloaked in mystery, the orthographic pipe fitting symbols can be drawn as a language of their own—silent yet eloquent. Among these, the elbow symbols hold a peculiar fascination, transforming complex piping networks into a visual symphony of angles and curves. Their orthographic representation—an intricate dance of lines and arcs—conveys the very essence of directional change, whispering secrets of fluid flow and structural intent.

Elbow symbols, in particular, are often depicted with a simple arc intersecting two straight lines, denoting the bend in the pipe. The degree of bend—be it 45°, 90°, or 180°—is subtly indicated through variations in the arc’s curvature, each a cryptic signature that guides the skilled eye through the labyrinth of piping diagrams. These symbols serve as the skeleton upon which the narrative of a piping system is woven, offering clarity amidst the chaos of complex schematics.

Understanding how the orthographic pipe fitting symbols can be drawn as is vital for anyone seeking mastery over technical drawings. They not only streamline communication but also preserve the gothic elegance of engineering artistry—each symbol a testament to the craftsmanship of diagrammatic storytelling.

Tee and Cross Fitting Symbols

Among the various orthographic pipe fitting symbols, tee and cross fittings are fundamental components in many piping systems. Their symbols serve as a visual shorthand in technical drawings, simplifying complex networks into understandable diagrams. When orthographic pipe fitting symbols can be drawn as, the tee fitting is typically represented by a T-shaped symbol, indicating a branch that splits the flow direction. Similarly, the cross fitting is shown as a plus sign (+), signifying a junction where four pipes intersect. These symbols are essential because they communicate the precise nature of connections without cluttering the schematic.

Understanding how to accurately depict tee and cross fittings in orthographic drawings helps ensure clarity and consistency across engineering documents. The symbols’ simplicity hides a wealth of information about flow direction, pipe sizes, and connection types. For example, a tee symbol with a specific orientation can illustrate whether the branch is upstream or downstream, while the cross symbol indicates a four-way junction. These visual cues make a significant difference in maintaining accuracy during construction or maintenance, highlighting the importance of mastering how orthographic pipe fitting symbols can be drawn as part of professional piping diagrams.

Reducer and Adapter Symbols

Reducer and adapter symbols are vital components in orthographic pipe fitting symbols. They illustrate how different pipe sizes connect, ensuring clarity in complex diagrams. A reducer symbol typically appears as a conical or stepped shape, indicating a decrease or increase in pipe diameter. Meanwhile, adapter symbols often resemble a straight or angled fitting, representing a connection between dissimilar pipe types or sizes. When orthographic pipe fitting symbols can be drawn as, these elements become straightforward yet precise visual cues. They simplify the communication of flow paths and connection specifics, especially in detailed piping schematics.

Understanding these symbols is crucial for accurate diagram interpretation. For example, a reducer with an upward orientation signals a reduction in pipe size downstream, while an adapter symbol clarifies the transition between different pipe standards. Clear depiction of reducers and adapters minimizes errors during installation and maintenance, highlighting the importance of mastering how orthographic pipe fitting symbols can be drawn as part of a professional piping system diagram. Recognising and employing these symbols correctly enhances the overall clarity and effectiveness of technical drawings.

Cap and Plug Symbols

In the intricate dance of piping schematics, the subtlety of cap and plug symbols often escapes the untrained eye—yet they are essential for conveying a system’s integrity with finesse. When orthographic pipe fitting symbols can be drawn as, these particular signs serve as silent sentinels, indicating points where pipes are sealed or terminated. A cap symbol, usually represented as a simple circle or rectangle at the end of a pipe line, signifies a closed end, while a plug symbol, often depicted as a small, threaded shape, indicates a removable or sealed connection. Their clarity ensures that even the most convoluted diagrams communicate precise intentions without a single misplaced word.

Understanding these symbols is akin to mastering a secret handshake—once learnt, they unlock a new realm of diagrammatic clarity. The elegance lies in their simplicity: a straightforward drawing that speaks volumes—no verbose annotations required. When orthographic pipe fitting symbols can be drawn as efficiently as a well-practised sketch, they transform complex schematics into comprehensible visual narratives, essential for both design precision and maintenance accuracy.

For those who appreciate the finer details of technical illustration, recognising the nuanced differences—such as the threaded nature of a plug versus the more straightforward cap—reveals a deeper mastery of piping diagrams. These symbols are not mere adornments but vital markers in the language of pipe fitting, silently guiding installers and engineers through the labyrinth of connections with minimal fuss. In the grand tapestry of orthographic representations, cap and plug symbols hold a distinguished place, quietly ensuring that every connection is understood and every endpoint properly signposted.

Valve Symbols in Orthographic Drawings

In the world of piping schematics, understanding the variety of common pipe fitting symbols is crucial. These symbols, when orthographic pipe fitting symbols can be drawn as, serve as universal language tools for engineers and technicians alike. They help streamline communication across complex projects, ensuring everyone is on the same page. From valves to specialised fittings, each symbol carries specific meaning, making detailed diagrams both clear and concise.

Valve symbols, in particular, demonstrate the versatility of orthographic pipe fitting symbols can be drawn as. These symbols are designed to represent different types of valves—such as gate, globe, or check valves—each with unique functions within the system. For example, a simple line with a circle or a specific shape indicates a valve’s position—open or closed. Recognising these symbols allows for quick interpretation of system status during installation or maintenance. When orthographic pipe fitting symbols can be drawn as, they act as visual shorthand, reducing the risk of miscommunication and errors.

In practice, understanding these symbols extends beyond mere recognition. For instance, a well-drawn valve symbol provides insight into the control points within a piping network. It’s not just about drawing a shape; it’s about accurately representing the function and orientation of each component. This level of detail enhances the overall clarity of piping diagrams, making complex systems easier to manage and troubleshoot.

Techniques for Drawing Orthographic Pipe Fitting Symbols

Line Types and Symbol Layers

In the realm of orthographic pipe fitting symbols, mastery over line types and symbol layers transforms technical drawings into clear, comprehensible maps of complex systems. The precision of these drawings hinges on selecting the appropriate line styles—solid, dashed, or phantom—that convey different connection types or movement directions. For instance, dashed lines often indicate hidden or future pipe routes, while solid lines mark current connections. Understanding how orthographic pipe fitting symbols can be drawn as with varied line types allows engineers and draughtsmen to create diagrams that are both functional and visually intuitive.

Layer management also plays a vital role. By assigning distinct layers to specific symbol categories—such as valves, reducers, or flanges—designers can easily toggle visibility, streamline editing, and ensure consistency across drawings. This approach prevents clutter and enhances clarity. Techniques like colour coding and layering enable seamless differentiation between pipe segments and fitting types, making complex schematics accessible at a glance. When drawing orthographic pipe fitting symbols, leveraging these layer strategies ensures a harmonious balance between detail and readability, elevating the entire drafting process.

3D Perspective vs. Standard Orthographic Views

In the intricate dance of engineering design, visual clarity is paramount—yet, the way orthographic pipe fitting symbols can be drawn as significantly influences how effectively these diagrams communicate complex systems. While standard orthographic views serve as the backbone of technical accuracy, exploring 3D perspectives introduces a nuanced depth that can unveil hidden connections and spatial relationships. This method transforms flat symbols into immersive representations, allowing viewers to intuitively grasp the orientation and interaction of pipe fittings within a broader assembly.

However, the decision to employ a 3D perspective versus traditional orthographic views hinges on the purpose of the diagram. For detailed fabrication or installation instructions, a standard orthographic projection offers precision and clarity. Conversely, for visualising system layout or troubleshooting, a 3D approach provides a more holistic understanding. The ability to seamlessly switch between these visual techniques underscores the importance of mastering how orthographic pipe fitting symbols can be drawn as, ensuring each depiction serves its unique communicative intent effectively.

Using Symbology for Clarification and Precision

In the labyrinth of piping design, clarity isn’t merely a virtue—it’s a necessity. The way orthographic pipe fitting symbols can be drawn as directly influences how effectively these diagrams communicate intricate systems. Precision in symbology transforms a complex network of connections into a visual language that engineers and technicians can swiftly interpret, avoiding costly mistakes and miscalculations. When employing techniques for drawing orthographic pipe fitting symbols, understanding the nuances of symbology becomes paramount—each line, curve, and annotation carries meaning beyond mere aesthetics.

To achieve this, many professionals adopt a methodical approach—using consistent line weights, clear legends, and standardised symbols. For example, a well-drawn elbow symbol in orthographic projection accurately reflects the true angle and orientation, ensuring that every stakeholder interprets the diagram uniformly. Incorporating a combination of precise line types and layers enhances clarity, allowing each symbol to stand out without ambiguity. This meticulous attention to detail elevates the quality of technical drawings, making them not just accurate but also intuitively comprehensible—an essential aspect when complex piping systems demand unambiguous communication.

Best Practices for Creating Accurate Pipe Fitting Diagrams

Standardized Symbol Sets and Reference Guides

In the intricate ballet of piping design, precision is king, and the use of standardized orthographic pipe fitting symbols can be drawn as a vital choreographer. When creating accurate diagrams, adhering to best practices isn’t merely a matter of aesthetics; it’s about fostering clarity and preventing costly misinterpretations. One of the most effective strategies involves employing comprehensive reference guides that delineate the standardised symbol sets, ensuring consistency across all drawings.

Moreover, meticulous attention to the layering of symbols and line types enhances diagram readability, especially when dealing with complex systems. For example, using distinct line weights for different pipe sizes or flow directions can prevent confusion and streamline communication among engineers and contractors. To maintain integrity, some professionals recommend developing a personalised style guide that aligns with industry standards, thereby fostering a shared language that transcends individual preferences.

Ultimately, the secret to mastering orthographic pipe fitting symbols can be drawn as lies in ongoing education and rigorous verification against authoritative standards. After all, a well-drawn diagram is worth a thousand words—provided those words are unambiguous and universally understood. More intriguingly, the craft of drawing these symbols becomes a subtle dance of precision, clarity, and a dash of artistic flair—reminding us that even in technical endeavours, elegance and function can coexist.

Consistent Use of Line Weights and Annotations

In the meticulous world of piping design, where a single misstep can cascade into costly errors, the best practices for creating accurate pipe fitting diagrams stand as the silent guardians of clarity. The consistent use of line weights and annotations isn’t merely an aesthetic choice but a strategic move to ensure every symbol’s message is unmistakably understood. When orthographic pipe fitting symbols can be drawn as varied visual cues—thicker lines for main pipes, dashed lines for hidden features—such distinctions become essential in navigating complex systems with finesse.

To elevate diagram precision, professionals often adopt a structured approach to layering. For instance, employing a hierarchy where flow directions are indicated with distinct arrowed lines, while pipe sizes are noted with precise annotations, creates a visual hierarchy that guides the eye seamlessly. A subtle yet impactful practice involves developing a personalised style guide, harmonising symbol styles with industry standards, thus fostering a shared visual language. After all, consistency in your orthographic pipe fitting symbols can be the difference between a clear blueprint and a confusing mess.

In essence, the craft of drawing these symbols is as much about subtlety as it is about accuracy. Balancing the artistic flair of clarity with the rigour of standards transforms technical drawings into powerful communication tools—proof that even the most intricate piping schematics can achieve elegance and function in one breath.

Tools and Software for Drawing Pipe Fitting Symbols

In the intricate dance of piping design, precision is paramount, and the tools chosen play a pivotal role in translating complex systems into clear, intelligible schematics. When considering how orthographic pipe fitting symbols can be drawn as, the software utilised must offer both nuance and flexibility. Modern CAD programs like AutoCAD Plant 3D or SolidWorks Piping stand as stalwart allies, enabling designers to craft symbols with meticulous detail and consistency. These tools provide a robust library of standard symbols, streamlining the process while maintaining adherence to industry conventions.

To elevate the fidelity of your diagrams, adopting specialised plugins or add-ons that facilitate custom symbol creation can be transformative. Such software empowers the draughtsman to develop personalised style guides, ensuring that each orthographic pipe fitting symbol aligns harmoniously with established standards. This consistency nurtures a shared visual language across teams and projects, transforming complex piping schematics into eloquent visual narratives. Ultimately, the choice of software and tools for drawing pipe fitting symbols can be the difference between confusion and clarity, turning technical minutiae into masterful communication.

Applications of Orthographic Pipe Fitting Symbols

Piping System Design and Drafting

In the intricate ballet of piping system design, the application of orthographic pipe fitting symbols can be drawn as a vital choreographer, orchestrating clarity amidst complexity. These symbols serve as the silent language that ensures engineers and technicians interpret every bend, junction, and valve with unerring precision. Beyond mere aesthetics, their strategic deployment in drafting elevates the accuracy of system schematics, reducing costly miscommunications. When utilised effectively, orthographic pipe fitting symbols can be drawn as a visual shorthand that condenses elaborate configurations into digestible diagrams, streamlining both the planning and troubleshooting stages.

Moreover, their role in piping system design and drafting extends into standardisation, fostering a common lexicon across diverse teams and projects. For example, in large-scale industrial facilities, a consistent set of symbols—such as those for reducers, tees, or valves—ensures seamless interpretation, even when teams span continents. This harmonised visual language not only accelerates installation but also facilitates future maintenance. Truly, the power of these symbols lies in their ability to marry simplicity with sophistication, making complex piping arrangements accessible at a glance.

Construction and Installation Blueprints

In the meticulous realm of construction and installation blueprints, the visual language of orthographic pipe fitting symbols can be drawn as a silent yet eloquent conversation, guiding skilled craftsmen through labyrinthine piping arrangements. These symbols serve as an indispensable tool—imagine a complex network of pipes reduced to a set of universally understood marks, each whispering its purpose with clarity. When applied with finesse, they transform convoluted schematics into coherent narratives, saving precious time and averting costly misinterpretations.

One might wonder, how do these symbols seamlessly integrate into the labyrinth of blueprints? The answer lies in their strategic utilisation—be it for indicating the precise location of valves, junctions, or reducers. For example, a simple circle with a line might represent a capped pipe, but when combined with colour coding or line weights, the entire system’s functionality becomes instantly comprehensible. When illustrating construction or installation blueprints, these symbols can be drawn as standardised shapes that communicate complex configurations effortlessly:

- Reducer connections illustrating pipe diameter changes.

- Elbow fittings denoting directional changes in piping runs.

- Valve symbols indicating control points within the system.

By employing these visual shorthand techniques, engineers and technicians can navigate the blueprint terrain with ease, ensuring that every bend and junction aligns perfectly in reality. Their application fosters consistency across projects—be it in offshore oil platforms or urban water treatment facilities—where the precision of orthographic pipe fitting symbols can be drawn as a testament to international standards. This consistency not only streamlines construction but also ensures future maintenance is a straightforward affair, avoiding the dreaded game of “find the hidden connection”.

Maintenance and Repair Documentation

In maintenance and repair documentation, the clarity provided by orthographic pipe fitting symbols is invaluable. Accurate schematics ensure that technicians can quickly identify key components, reducing downtime significantly. When orthographic pipe fitting symbols can be drawn as standardised shapes, it simplifies troubleshooting and system upgrades. These visual cues help prevent errors during repairs, making the process more efficient and less prone to mistakes.

For example, clear symbols indicating valve positions or pipe junctions enable maintenance teams to locate specific points in complex systems swiftly. This consistency across documentation means fewer misinterpretations and smoother communication between design engineers and field technicians. Employing these symbols in repair manuals and inspection reports guarantees that every stakeholder understands the piping network with precision. It’s no exaggeration to say that proper use of orthographic pipe fitting symbols can be drawn as a critical factor in ensuring effective and safe maintenance practices.

- Precise identification of pipe diameters and connections

- Clear communication of control points like valves and reducers

- Efficient planning for system upgrades or repairs

Ultimately, integrating these symbols into maintenance documentation elevates the entire process—saving time, reducing costs, and improving safety standards. When orthographic pipe fitting symbols can be drawn as part of detailed repair schemas, the entire workflow becomes more streamlined and reliable.

Educational and Training Materials

In the realm of education and training, the visual language of orthographic pipe fitting symbols holds unparalleled power. When aspiring engineers and seasoned technicians alike immerse themselves in these symbols, they gain a lexicon that transcends mere notation—it’s a gateway to mastery. The ability to interpret and replicate these symbols ensures that knowledge flows seamlessly from classroom to field, transforming complex systems into comprehensible narratives.

For instructional purposes, orthographic pipe fitting symbols can be drawn as part of detailed diagrams, which serve as both teaching tools and reference standards. These schematic representations make it possible to simulate real-world scenarios, fostering a deeper understanding of piping systems. As a result, trainees can grasp the intricacies of system components—valves, reducers, junctions—with clarity that is both visual and conceptual. This approach not only accelerates learning but also cements the importance of standardisation in piping practices.

In addition, educational materials that employ these symbols elevate the pedagogical experience, making technical concepts accessible without sacrificing precision. When orthographic pipe fitting symbols can be drawn as consistent, standardised shapes, they become invaluable assets in diverse training modules, from beginner courses to advanced certifications. Such visual clarity cultivates confidence and competence, ensuring that future professionals are equipped to design, troubleshoot, and maintain piping systems with the finesse of a seasoned artisan.

Future Trends in Pipe Fitting Symbol Representation

Digital and Automated Drawing Technologies

As technology continues to evolve at a rapid pace, so too does the way we represent orthographic pipe fitting symbols can be drawn as. The future of digital and automated drawing technologies promises to revolutionise the industry, making pipe system diagrams more precise and easier to interpret. Advanced software solutions now incorporate intelligent symbol libraries that adapt to different standards and conventions, reducing errors and improving clarity.

One of the most significant trends is the integration of Building Information Modelling (BIM). This allows for seamless collaboration among engineers, architects, and contractors by embedding orthographic pipe fitting symbols directly into 3D models. Enhanced visualisation techniques mean that pipe fitting symbols can be rendered with greater detail, enabling clearer communication in complex piping systems.

Moreover, the adoption of artificial intelligence and machine learning is set to transform the creation of pipe fitting diagrams. These technologies can automatically generate or verify orthographic pipe fitting symbols can be drawn as, based on input data and predefined standards. This not only streamlines workflow but also ensures consistency across projects. As these innovations become more mainstream, expect to see a shift towards fully automated drafting environments that enhance accuracy, minimise waste, and accelerate project timelines.

Standardization Developments

As digital technology continues its relentless march forward, the landscape of pipe fitting symbol standardisation is poised for a transformative shift. The future trends in the representation of orthographic pipe fitting symbols can be drawn as with an unprecedented level of precision and consistency, thanks to innovations in automation and data integration. This evolution is not merely about aesthetics; it fundamentally enhances clarity and reduces costly errors in piping system design.

One compelling development is the increasing adoption of unified standards for orthographic pipe fitting symbols, which promote interoperability across diverse software platforms and project teams. Moreover, the integration of blockchain-like validation processes ensures that symbol representations adhere strictly to industry norms, fostering trust and accuracy. As a result, the creation of comprehensive, standardised symbol sets becomes more accessible, supporting clearer communication in complex piping projects.

Furthermore, the proliferation of visualisation tools leverages augmented reality and virtual environments, enabling stakeholders to interpret pipe fitting diagrams with greater contextual understanding. The ongoing convergence of these technological advances hints at a future where the creation of orthographic pipe fitting symbols can be drawn as seamlessly as thought itself—integrating sophistication with simplicity, and precision with practicality. As these developments unfold, expect to see a new era of standardisation that elevates both the craftsmanship and the clarity of piping system documentation.

Integration with 3D Modeling and Simulation Software

In the shadowed corridors of modern piping design, the future whispers of integration that promises to transform the craft entirely. The orthographic pipe fitting symbols can be drawn as not merely static diagrams but as dynamic elements woven into the very fabric of 3D modelling and simulation software. This convergence reveals a new realm where precision is no longer a distant ideal but an immediate reality.

Imagine a world where the orthographic pipe fitting symbols can be drawn as seamlessly within immersive virtual environments as they are on traditional blueprints. Here, the symbology becomes alive, allowing engineers and designers to traverse virtual piping labyrinths with unprecedented clarity. The advent of sophisticated CAD tools merges the symbolic language of pipe fittings with complex simulations, offering a visual fidelity that borders on the supernatural.

Such technological symbiosis fosters a deeper understanding of piping systems, where the symbols serve as gateways to intricate virtual prototypes—enabling real-time adjustments and error detection. The integration of these symbols into 3D environments not only enhances accuracy but also transforms the design process into a hauntingly efficient dance of light and shadow. As the orthographic pipe fitting symbols can be drawn as part of these advanced digital realms, the lines between conceptual and tangible dissolve, ushering in an era of unparalleled craftsmanship and reliability.

0 Comments