Understanding Head Loss in Pipe Fittings

Definition of Head Loss – What is head loss and why it matters in piping systems

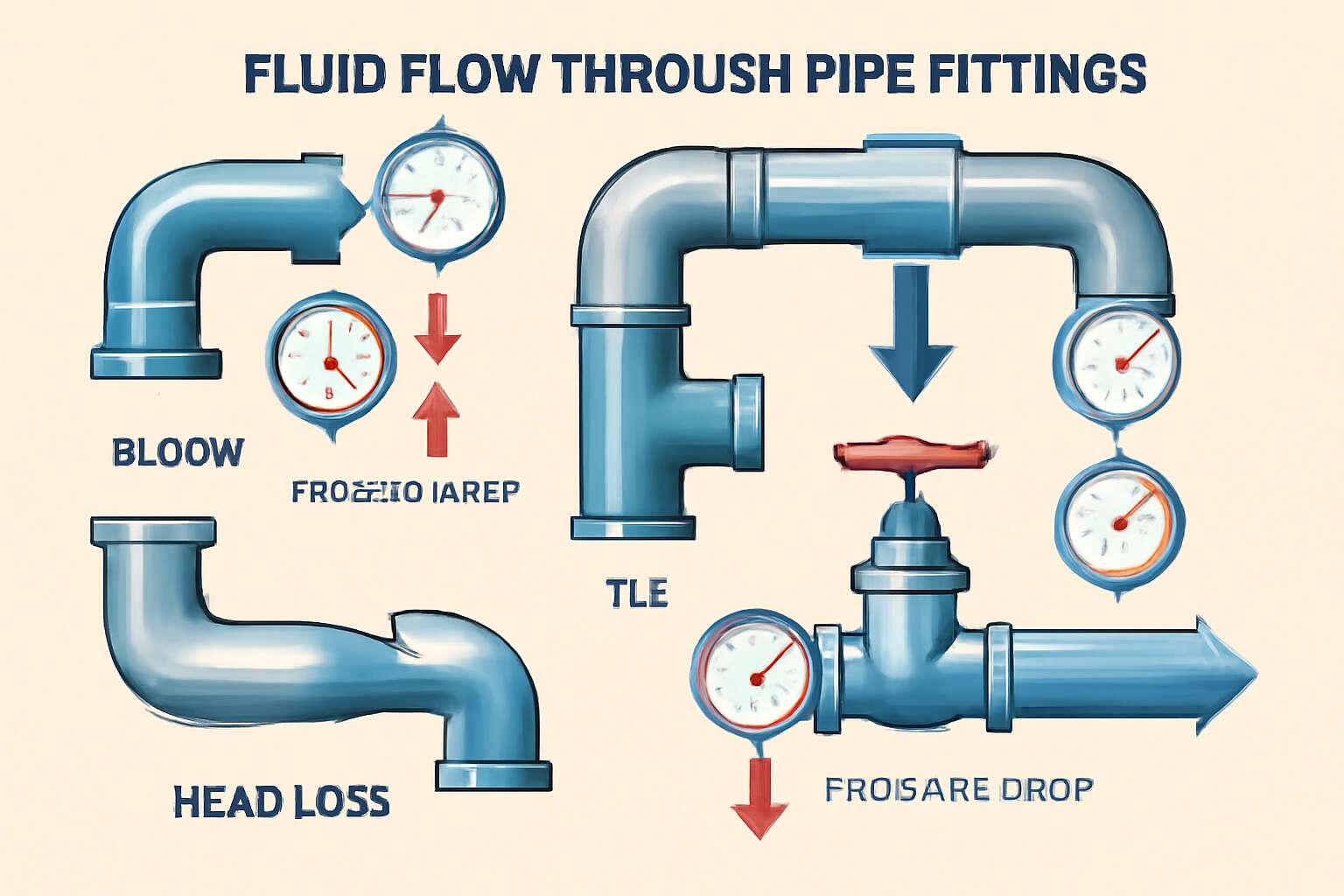

Imagine your piping system as a bustling highway, where fluids are the cars zooming past at high speed. Now, head loss of pipe fittings is like the unexpected potholes and sharp turns that slow down traffic—except in this case, it’s the energy that’s lost as fluid navigates through elbows, tees, and valves. Understanding head loss is crucial because it directly impacts how efficiently your system operates, affecting everything from pump sizing to energy consumption.

In simple terms, head loss is the reduction in the total head (or energy) of the fluid as it flows through pipe fittings. This energy loss occurs due to turbulence and friction, which turn what should be a smooth ride into a bumpy journey. The more complex or restrictive a fitting, the greater the head loss of pipe fittings, ultimately leading to increased operational costs and potential system failures.

To put it in perspective, consider this: every bend, valve, or sudden enlargement in the pipe acts as a mini obstacle that saps energy from the flowing fluid. Recognizing these losses is essential for engineers aiming to optimize piping systems and avoid unnecessary expenditure. After all, a well-designed system minimizes head loss, ensuring your fluid keeps moving without demanding more power than necessary.

Types of Head Loss – Frictional Vs. Fittings-related head loss

In the shadowed corridors of fluid dynamics, understanding the head loss of pipe fittings becomes an obsession—an unending quest to tame the chaos within piping systems. Not all losses are born equal; some whisper softly, while others roar like a distant thunderstorm. Here, we delve into the two primary culprits behind the mysterious reduction of energy—the silent frictional forces and the more sinister fittings-related head loss.

Frictional head loss, the most insidious of these, arises from the constant resistance the fluid encounters as it brushes against the inner walls of pipes, gradually sapping its momentum. But lurking within the twists, turns, and junctions are fittings-related head loss—those treacherous points where turbulence reigns supreme. These fittings, whether elbows, tees, or valves, act as miniature labyrinths, each amplifying the head loss of pipe fittings by disrupting the smooth flow and generating eddies that drain energy from the system.

- The sharp bend of an elbow creates turbulence, turning a once steady stream into a chaotic maelstrom, increasing head loss significantly.

- Valves, especially when partially closed, act as choke points—magnifying the head loss of pipe fittings and demanding more power to maintain flow.

- Tees and reducers introduce sudden enlargements or constrictions, turning the flowing fluid into a tempest of energy dissipation.

Importance of Evaluating Head Loss – Impact on system efficiency and energy consumption

Understanding head loss in pipe fittings is more than a mere technicality; it’s the subtle art of avoiding costly inefficiencies in fluid systems. When we overlook the impact of pipe fittings on head loss, we risk turning a well-oiled hydraulic symphony into a cacophony of turbulence and energy drain. Each fitting—be it a humble elbow or a complex valve—acts as a catalyst for energy dissipation, subtly undermining the system’s integrity and increasing operational costs.

In South Africa’s dynamic industrial landscape, evaluating the head loss of pipe fittings becomes a strategic necessity. A minor oversight here can escalate into a significant energy drain, wasting power and inflating maintenance bills. Recognizing the importance of these tiny, yet impactful components ensures optimal flow performance and system longevity. After all, in the realm of piping, even the smallest twist or turn can have outsized consequences—making the assessment of head loss of pipe fittings an essential aspect of efficient engineering.

Factors Influencing Head Loss in Pipe Fittings

Fitting Geometry – Shape, size, and type of fittings affecting flow resistance

In the intricate dance of fluid dynamics, the head loss of pipe fittings often plays the role of an uninvited guest—slyly siphoning off energy and causing chaos in your piping system. The geometry of fittings isn’t just a matter of aesthetic appeal; it determines how much flow resistance is introduced into the system. Think of fittings as the quirky characters in a plumbing soap opera—each with a unique shape, size, and type that influences the flow’s temperament.

Shape and size are crucial; a sharp elbow or a sudden expansion can turn a smooth stream into a turbulent mess, dramatically increasing head loss. For example, a 90-degree bend creates more head loss than a gentle curve because it forces the fluid to change direction abruptly. Similarly, larger fittings tend to reduce head loss, but only up to a point—sometimes, bigger isn’t always better in the world of pipe fittings.

Understanding the impact of fitting geometry is essential, especially in South African systems where energy efficiency and cost savings are paramount. Here’s a quick rundown of how different fitting types influence head loss of pipe fittings:

- Elbows and bends—major culprits in increasing head loss due to turbulence

- Reducers—alter flow velocity, impacting system pressure

- Tees and junctions—introduce flow splits, often leading to uneven head loss distribution

So, when designing or troubleshooting a piping system, pay close attention to the shape, size, and type of fittings—because every twist and turn in your pipes can silently sap your system’s efficiency and your patience!

Flow Rate and Velocity – How increased flow velocity impacts head loss

Flow velocity plays a pivotal role in the head loss of pipe fittings. As velocity increases, so does the turbulence within the pipe. This turbulence causes energy to dissipate faster, resulting in higher head loss. In fact, even a slight boost in flow rate can lead to a significant spike in head loss, especially at points where fittings disrupt the smooth flow. The key is understanding that head loss isn’t just about pipe length or roughness — fittings such as elbows, tees, and reducers inject additional resistance, which intensifies with rising velocity.

When dealing with high flow rates, consider the impact on the system’s overall efficiency. Increased velocity magnifies the effect of head loss of pipe fittings, forcing pumps to work harder and consuming more energy. A well-balanced system minimizes abrupt changes in flow velocity, reducing unnecessary head loss. In South African systems where energy efficiency is vital, understanding the interplay between flow rate, velocity, and head loss of pipe fittings helps optimize design and operation. Remember, every increase in velocity can amplify head loss, making it essential to manage flow carefully from the start.

Pipe Material and Surface Roughness – Effects of pipe and fitting material on flow resistance

The materials chosen for pipes and fittings can significantly influence the head loss of pipe fittings, shaping the overall efficiency of a piping system. A rougher surface inside the pipe or fitting introduces more resistance, causing turbulence that hampers smooth flow and elevates head loss. Conversely, smoother materials like PVC or polished stainless steel help maintain laminar flow, minimizing energy dissipation. It’s a delicate balance—using durable, corrosion-resistant materials that also promote low flow resistance is key to optimizing system performance.

Surface roughness isn’t just about aesthetics; it directly impacts flow resistance. For instance, cast iron fittings tend to have a higher surface roughness compared to modern plastics, resulting in increased head loss of pipe fittings. When selecting materials, consider the flow rate and the potential for buildup or corrosion that could elevate roughness over time.

- Material durability

- Surface finish quality

These factors can either mitigate or exacerbate head loss, especially at critical points where fittings disrupt the flow path.

Fluid Properties – Viscosity and density considerations

The fluid’s properties—its viscosity and density—play a subtle yet profound role in shaping the head loss of pipe fittings. Imagine water flowing through a labyrinth of corridors—its resistance varies not just with the twists and turns but also with its intrinsic nature. Thicker, more viscous fluids tend to cling to the pipe walls, amplifying friction and consequently increasing the head loss of pipe fittings. Conversely, lighter fluids like certain chemicals or gases glide more effortlessly, reducing resistance.

Density, too, acts as a silent influencer, affecting how momentum is transferred through twists and turns. When dealing with high-density fluids, even minor irregularities in fitting geometry can cause notable turbulence. To illustrate, consider a scenario where a sudden expansion or contraction in the fitting causes energy dissipation—this effect is magnified in fluids with higher viscosity and density. Understanding these fluid properties helps engineers anticipate the head loss of pipe fittings, ensuring that systems are both efficient and resilient.

Common Types of Pipe Fittings and Their Head Loss Characteristics

Elbows and Bends – Impact on head loss and typical loss coefficients

Elbows and bends are among the most common types of pipe fittings, yet their impact on head loss can’t be underestimated. These fittings introduce turbulence into the flow, causing additional resistance that must be overcome by the pumping system. Typically, the head loss of pipe fittings like elbows and bends is quantified by loss coefficients, which vary depending on their angle and radius. For example, a standard 90-degree elbow generally has a higher loss coefficient than a gentle bend, directly translating into increased energy consumption.

Understanding the head loss of pipe fittings is crucial for optimizing system efficiency. High head loss not only means more power needed to push fluids through the pipeline but also leads to increased operational costs. For this reason, selecting fittings with appropriate geometry—such as long-radius bends instead of sharp elbows—can significantly reduce flow resistance. An

- important consideration is the fitting’s shape and size, which influence the turbulence and pressure drop experienced downstream.

In South Africa’s diverse infrastructure landscape, where energy efficiency is vital, knowing how elbows and bends impact head loss can make a real difference. Every degree of bend or change in pipe direction adds to the cumulative head loss of pipe fittings, emphasizing the importance of precise engineering and material choices. The nuances of flow dynamics remind us that even small design decisions ripple through the entire system’s performance, often in unexpected ways.

Tees and Crosses – Flow disruption and associated head loss

Not all pipe fittings are created equal when it comes to their impact on head loss. Tees and crosses are prime examples of fittings that can significantly disrupt flow, leading to increased head loss of pipe fittings. These junctions cause flow separation and turbulence, which in turn elevate the pressure drop downstream. Unlike smooth bends or long-radius elbows, tees and crosses introduce abrupt changes in flow direction, resulting in higher energy dissipation.

Flow disruption caused by these fittings is particularly critical in systems where maintaining steady flow and minimizing energy costs matter. In fact, the head loss of pipe fittings like tees and crosses can account for a substantial portion of the total head loss in complex piping networks. For systems in South Africa’s infrastructure, this means that careful selection of fitting type can lead to better efficiency and reduced operational expenses.

- Flow separation and turbulence generation

- Increased pressure drop and energy consumption

- Higher head loss compared to smoother fittings

Understanding these head loss characteristics helps engineers design more effective piping systems, where every component’s influence on flow dynamics is carefully considered. The shape and configuration of tees and crosses are key factors that directly affect their head loss contribution. In regions where energy efficiency is vital, such as South Africa’s diverse infrastructure, optimizing these fittings is not just a technical choice but a practical necessity.

Valves (Gate, Ball, Check) – Variable head loss based on valve position and type

In the shadowed corridors of fluid dynamics, valves stand as silent sentinels—each one whispering tales of flow resistance and energy sapping. Whether it’s a gate valve, a ball valve, or a check valve, their head loss of pipe fittings varies dramatically with their position and intended function. A fully closed gate valve, for instance, may present a near-impenetrable barrier, causing a significant spike in head loss. Conversely, a partially open ball valve might subtly modulate flow, but never without some toll on system efficiency.

Understanding these subtle distinctions is vital. Valves can cause variable head loss depending on their type and operational state. For example, check valves, which prevent backflow, often introduce turbulent zones that exacerbate head loss of pipe fittings, leading to increased energy consumption. Engineers in South Africa’s intricate infrastructure face the challenge of balancing operational needs with the relentless march of flow resistance. The choice of valve and its configuration can make or break the delicate equilibrium within a piping network.

- Type of valve

- Position within the system

- Flow rate and pressure conditions

These factors intertwine like the roots of an ancient tree, each influencing the overall head loss of pipe fittings and shaping the efficiency of the entire system. When every drop of energy must be conserved in the face of relentless pressure, understanding the head loss characteristics of valves becomes a dark art—an essential for those who dare to tame the underground arteries of South Africa’s sprawling infrastructure.

Reducers and Expanders – Effect of diameter changes on head loss

Within the labyrinth of piping systems, the subtle dance of fluid encounters many hurdles—none more intricate than the head loss of pipe fittings. Among these, reducers and expanders serve as gateways that alter the diameter of flow pathways, but their impact on system efficiency is profound. When a pipe narrows, the fluid accelerates, yet this transformation often spawns turbulence, leading to a spike in head loss of pipe fittings. Conversely, expanding a pipe’s diameter can reduce velocity but may introduce flow separation, also contributing to increased head loss.

Imagine a journey where each change in diameter whispers secrets of energy surrender. The sharper the transition—say, a sudden reducer—the greater the head loss, as turbulence and eddy formations swell behind the constriction. Smooth, gradual transitions, however, can mitigate these losses, creating a more harmonious flow. This delicate balance underscores the importance of understanding how diameter changes influence head loss of pipe fittings, especially in the complex infrastructure of South Africa’s expansive pipeline networks.

- Gradual reducers and expanders are preferred for minimizing head loss.

- Sudden changes in diameter often cause turbulent eddies, amplifying head loss significantly.

- The ratio of diameter change impacts flow disruption, with larger differences leading to greater head loss of pipe fittings.

In the grand tapestry of fluid mechanics, the effect of diameter adjustments on head loss is akin to the shifting tides—subtle yet powerful. As flow velocity increases through a reducer, the risk of turbulence surges, making the careful selection of fitting geometry essential for maintaining system integrity. Whether in municipal water networks or industrial applications across South Africa, these nuances in pipe fitting design can spell the difference between seamless operation and energy drain.

Calculating Head Loss in Pipe Fittings

Use of Loss Coefficients (K-factors) – Determining head loss using K-values for different fittings

In the intricate dance of fluid dynamics within piping systems, the head loss of pipe fittings often plays a silent yet pivotal role. To quantify this subtle resistance, engineers turn to the use of loss coefficients, or K-factors, which act as the poetic measure of a fitting’s impact on flow energy. These coefficients are not arbitrary; each fitting—elbows, tees, valves—has a unique K-value, reflecting its geometric complexity and surface roughness.

Determining the head loss of pipe fittings involves a straightforward yet revealing formula: the velocity head multiplied by the K-value. This calculation illuminates how even a slight bend or sudden expansion can sap energy from the flowing medium, akin to a gust of wind whispering through a narrow canyon. Understanding these K-values allows for precise system design, ensuring energy efficiency and optimal flow performance.

- Elbows typically have higher K-values due to directional change, causing more head loss.

- Valves and reducers introduce variable head loss depending on their state and size.

- The shape and surface finish of fittings significantly influence their K-coefficient, affecting the overall head loss of pipe fittings.

The Darcy-Weisbach Equation – Applying it to fittings for head loss calculation

Calculating the head loss of pipe fittings using the Darcy-Weisbach equation unveils the hidden energy drain in your piping system. This fundamental equation relates the head loss to the flow velocity, pipe diameter, and fluid properties, but it’s the inclusion of the K-factor that transforms it into a powerful tool for fittings analysis. When fluid navigates through elbows, tees, or valves, the head loss manifests as a tangible reduction in flow energy, silently impacting efficiency.

To quantify this head loss of pipe fittings, multiply the velocity head by the fitting’s specific K-value. This approach captures the effect of different geometries and surface conditions. For example, an elbow with a high K-value causes more head loss than a smooth, gentle bend. Understanding this relationship enables engineers to predict pressure drops accurately, ensuring the system remains optimized for energy efficiency and longevity.

- Calculate the velocity head: ( frac{V^2}{2g} )

- Identify the K-value based on fitting type and condition

- Apply the formula: Head loss = K × velocity head

This method offers a clear window into how each fitting contributes to the overall head loss of pipe fittings, revealing potential choke points and energy leaks within complex piping networks. Recognizing these effects is crucial for designing systems that are both robust and sustainable, especially in regions like South Africa where energy conservation is paramount.

Empirical Formulas and Charts – Using manufacturer data and standardized charts

In the shadowed corridors of hydraulic design, the head loss of pipe fittings lurks unseen—yet its impact is profound. To decode this elusive energy drain, engineers often turn to empirical formulas and standardized charts, vital tools that transform dark complexity into tangible insight. Manufacturer data, meticulously gathered from real-world testing, illuminate the path, revealing the precise head loss associated with specific fittings. These charts serve as a secret map, guiding designers through the labyrinth of flow resistance, especially in regions like South Africa where energy efficiency is a precious commodity.

By referencing these trusted sources, the calculation of head loss becomes both more accurate and less guesswork-laden. Fittings such as elbows, tees, and valves come with published K-values—coefficients that encapsulate their geometric and surface roughness characteristics. Using these, the head loss of pipe fittings can be swiftly estimated, ensuring that each bend and junction contributes its fair share to the overall system efficiency.

For those seeking a precise snapshot, the process often involves a simple calculation: determine the velocity head, then multiply by the fitting’s K-value. This approach, blending empirical wisdom with standard charts, unveils the silent energy leaks within complex piping networks, revealing choke points that threaten system stability and longevity.

In essence, harnessing manufacturer data and standardized charts for head loss of pipe fittings transforms an opaque challenge into a manageable piece of engineering art—especially vital in contexts demanding energy conservation and optimal flow management. With each calculated head loss, the shadows recede, paving the way for piping systems that are both resilient and efficient in the darkened landscapes of South Africa’s infrastructure.

Examples and Sample Calculations – Step-by-step calculation approaches

Calculating the head loss of pipe fittings can feel like deciphering a cryptic code—every bend, junction, and valve adds a hidden layer to the system’s energy budget. To unravel this mystery, engineers rely on a step-by-step approach that transforms complexity into clarity. The process begins with understanding the flow velocity and the specific fitting’s K-value, a coefficient that captures the flow resistance inherent in its geometry. Combining these elements reveals how much energy is lost each time fluid navigates a turn or obstacle.

For example, consider a standard elbow with a known K-value. First, determine the velocity head (V²/2g) using the flow rate and pipe diameter. Then, multiply this by the fitting’s K-value to find the head loss contributed by that fitting. This straightforward calculation enables precise system modeling, especially critical in South Africa where energy efficiency is paramount. By systematically applying these principles, engineers can identify potential choke points and optimize piping layouts for resilience and longevity.

- Calculate the velocity head based on flow rate and pipe diameter.

- Identify the K-value for the specific fitting from manufacturer data or standardized charts.

- Multiply the velocity head by the K-value to find the head loss of pipe fittings.

This method offers clarity amid the chaos—each step revealing a fragment of the system’s energy dynamics. When dealing with complex piping networks, such meticulous calculations help prevent costly inefficiencies and ensure the system’s integrity. The head loss of pipe fittings, once shrouded in mystery, becomes a quantifiable metric—an essential tool for safeguarding infrastructure against the silent drain of energy.

Design Considerations to Minimize Head Loss

Selecting Appropriate Fittings – Choosing fittings with lower resistance coefficients

When designing piping systems, selecting appropriate fittings becomes crucial in minimizing head loss of pipe fittings and maintaining optimal flow efficiency. Fittings with lower resistance coefficients can dramatically reduce pressure drops, saving energy and prolonging system lifespan. It’s tempting to choose standard fittings, but understanding the impact of fitment geometry and material composition can make all the difference. For instance, streamlined elbows and smooth-bore tees often possess lower K-factors, which directly influence head loss of pipe fittings.

In rural South African settings, where energy conservation and system reliability are vital, opting for fittings with lower resistance coefficients is a practical step. A well-chosen fitting not only mitigates head loss but also ensures smoother flow and less wear on pumps and valves. The key is evaluating each fitting’s flow disruption potential, considering both its shape and the flow rate. An awareness of how these factors interplay can lead to more sustainable and cost-effective pipeline systems across diverse terrains.

Optimizing Pipe Layout – Strategic routing to reduce number of fittings

Strategic routing in pipe layout isn’t just about neatness—it’s a game-changer for reducing head loss of pipe fittings. When designing a pipeline, every bend, junction, and connection can introduce turbulence, increasing resistance and energy consumption. Thoughtful routing minimizes the number of fittings, especially sharp elbows and unnecessary tees, which are notorious for exacerbating head loss of pipe fittings.

Opting for a layout that follows the natural terrain and flow path helps streamline the system. For instance, long, sweeping bends with gentle angles often generate lower head loss compared to multiple sharp turns. This approach not only conserves energy but also extends the lifespan of pumps and valves, crucial in rural South African settings where reliability is paramount.

- Plan routes that reduce the need for frequent fittings.

- Use gradual curves instead of sharp angles to maintain smooth flow.

- Incorporate straight runs where possible, limiting the disruption caused by fittings.

By prioritizing the optimal pipe route, engineers can significantly diminish head loss of pipe fittings, ensuring a more efficient and sustainable piping system across diverse terrains. The secret lies in understanding how layout and geometry influence flow resistance—an insight that transforms ordinary pipelines into resilient, energy-efficient arteries of infrastructure.

Material Choices – Using smoother materials to reduce friction

Choosing the right materials for your piping system isn’t just about durability or cost—it’s a strategic move to minimize the head loss of pipe fittings. Smoother internal surfaces reduce friction, allowing fluids to flow with less resistance. In regions like South Africa, where energy efficiency and system longevity are critical, material selection can make all the difference. Materials such as HDPE (High-Density Polyethylene) or polished stainless steel are renowned for their low surface roughness, significantly decreasing head loss of pipe fittings.

In addition to material choice, the surface finish plays a pivotal role. Polished interiors foster a streamlined flow, which means fewer turbulence zones and reduced head loss. For engineers and installers, understanding the impact of surface roughness on head loss of pipe fittings is essential. Incorporating smoother materials not only enhances system performance but also cuts operational costs over time.

Sometimes, opting for fittings designed with low-resistance geometries—like long-radius elbows or streamlined tees—works synergistically with material choices. These elements, combined with smooth materials, create a piping network that keeps fluid dynamics optimal, conserving energy. As the saying goes, “smooth sailing” in pipeline design is often a matter of selecting the right material and geometry, especially when striving to reduce head loss of pipe fittings in complex terrains.

Flow Control Devices – Implementing valves and controls efficiently

In the intricate dance of fluid dynamics, the way we control flow can either hinder or propel efficiency. Valves and flow control devices are the silent gatekeepers—each decision impacting the head loss of pipe fittings in profound ways. When poorly managed, these elements introduce turbulence, increasing resistance and sapping energy from the system. But when thoughtfully implemented, they become catalysts for smoother operation, conserving vital energy in complex terrains like South Africa’s expansive pipeline networks.

Strategic placement and selection of flow control devices can significantly influence the head loss of pipe fittings. For instance, using streamlined valves such as butterfly valves or globe valves reduces unnecessary turbulence. In some cases, integrating flow restrictors or variable speed pumps can optimize flow without adding excessive head loss. Remember, every valve position, whether fully open or partially closed, alters the head loss profile—making it crucial to evaluate their operation within the broader system.

Moreover, incorporating flow control devices with low resistance coefficients—like specially designed check valves or ball valves—can enhance overall efficiency. These components, when paired with proper pipe layout and minimal fitting geometries, prevent the accumulation of turbulence zones. The goal isn’t just to move fluid but to do so with grace, conserving energy and extending the longevity of the system. After all, controlling flow isn’t merely a technical necessity; it is a moral commitment to sustainable engineering—an acknowledgment that every drop, every joule, counts.

Tools and Resources for Engineering and Design

Head Loss Calculation Software – Overview of industry tools and simulators

When it comes to engineering head loss calculation, having the right tools and resources at your fingertips can turn a complex puzzle into a manageable task. With industry-leading software and simulators, engineers can accurately predict how fittings will impact overall system efficiency—saving time, money, and headaches down the line. These tools often incorporate empirical data, the Darcy-Weisbach equation, and standardized charts, making head loss of pipe fittings calculations more precise than ever before.

Popular software options like PipeFlow Expert, AFT Fathom, and FlowMaster provide intuitive interfaces and robust databases of fitting loss coefficients. They allow quick scenario testing—ideal for optimizing pipe layout and selecting fittings with lower resistance coefficients. For those who prefer a more hands-on approach, several online calculators and spreadsheets are available, often backed by manufacturer data and detailed loss coefficients (K-factors). Whether you’re designing a new water system or troubleshooting an existing setup, leveraging these tools ensures a more accurate assessment of head loss of pipe fittings, ultimately leading to energy-efficient and cost-effective solutions.

Fitting Loss Coefficient Tables – Where to find reliable data sources

In the intricate dance of fluid dynamics, the head loss of pipe fittings often plays the role of an unassuming yet pivotal character. To unravel this mystery, engineers turn to a tapestry of reliable data sources and tables that hold the secrets of flow resistance coefficients. These fitment loss coefficient tables serve as the compass guiding the selection of fittings with optimal performance, ensuring that every turn in the piping system is accounted for with precision.

Locating trustworthy data sources is essential. Industry-standard references like the Crane Technical Paper No. 410, the Darcy-Weisbach chart, and manufacturer catalogs provide a treasure trove of empirical data. These resources often contain detailed K-factors—those elusive loss coefficients—that quantify the head loss of pipe fittings with remarkable clarity. For those seeking digital convenience, online calculators and databases from reputable suppliers offer quick access to these vital figures, streamlining the design process and enhancing system efficiency.

In the quest for accuracy, consulting multiple data sources can illuminate the subtle variations in fitting geometries and flow conditions. Whether it’s a simple elbow or a complex tee, understanding the head loss associated with each fitting ensures that the overall system operates smoothly, conserving energy and reducing operational costs. After all, in the realm of fluid transport, every detail—no matter how small—contributes to the grand symphony of fluid flow.

Guidelines and Standards – Relevant industry standards (e.g., ASME, ISO)

In the realm of fluid dynamics, precise control of the head loss of pipe fittings can make or break a piping system’s efficiency. Engineers often rely on reputable tools and standards to navigate this complex landscape, ensuring every bend, tee, and valve contributes to smooth, energy-efficient flow. When it comes to design guidelines, industry standards such as ASME and ISO serve as unyielding beacons—setting the benchmark for calculating and managing head loss of pipe fittings across diverse applications.

These standards provide comprehensive frameworks, including empirical data and formulas, that help engineers accurately predict flow resistance. For instance, ASME B31.3 covers process piping, offering critical insights into fitting loss coefficients, while ISO 5167 presents methodologies for flow measurement that account for head loss of pipe fittings. Relying on such authoritative resources ensures consistency, safety, and performance in piping projects.

In addition to formal standards, numerous software tools and digital resources streamline the process. Industry-leading head loss calculation software integrates these standards, enabling quick, reliable assessments. Whether through digital databases containing K-factors or advanced simulation platforms, these tools help optimize pipeline layouts and select fittings with minimal resistance, ultimately conserving energy and reducing operational costs.

Relevant Industry Standards for Managing Head Loss of Pipe Fittings

- ASME B31.3 (Process Piping)

- ISO 5167 (Flow Measurement and Head Loss Calculations)

- ANSI/ASME B16.9 (Factory-Made Wrought Steel Buttwelding Fittings)

- API Standards for Oil and Gas Pipelines

In the high-stakes game of piping system design, adherence to these standards ensures the head loss of pipe fittings remains predictable and manageable. When every fitting’s impact on flow is understood and optimized, the entire system operates with surgical precision—reducing energy loss and extending the lifespan of critical infrastructure. That’s the power of industry-standard guidelines—transforming chaos into clarity in the dance of fluid flow.

Professional Consultation – When to seek expert assistance

Managing the head loss of pipe fittings requires precision and expertise. When system complexities escalate or when high efficiency is non-negotiable, seeking professional consultation becomes essential. Experts equipped with advanced tools can identify subtle flow restrictions that may not be apparent through basic calculations. This ensures your piping system runs smoothly, saving energy and reducing operational costs.

Modern engineering relies heavily on specialized software and digital resources for accurate head loss assessments. These tools incorporate industry standards, such as ASME and ISO, offering reliable data on fitting loss coefficients and flow behavior. For complex systems, consulting with fluid dynamics specialists can help optimize pipe layout and fitting selection, minimizing head loss of pipe fittings and improving overall system performance.

When should you consider expert assistance? If your project involves high-pressure systems, unusual pipe geometries, or critical safety requirements, professional guidance can prevent costly errors. Engaging with experienced engineers ensures the head loss of pipe fittings is correctly evaluated, leading to more precise designs and long-term reliability. Sometimes, a quick consultation can make all the difference in achieving maximum efficiency in your piping system.

0 Comments